Wow! By some coincidence, the last post to this thread was exactly a year ago (where did the year go?). I bought a

mill last year and have used it for many things unrelated to my tractor. Anyway, I have finally gotten back to this project and have an update.

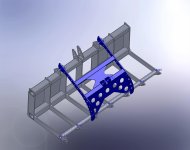

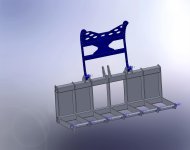

Last month I found someone to plasma cut the parts for me, so I now have everything I need except for the pins. The rake is tacked together, and I'm working on boring the holes for pin bushings in all the parts that need them. I'll tack the grapple together after I get the bushings in place so I can hold it all together with pins while I weld it.

A few changes:

- I decided to go with 1/4" A572 grade 70 plate instead of 3/8" A36. This will save about 33% of the weight while providing about 30% more strength.

- I decided to go with 3/16" wall A500 square tube instead of 1/4" wall for the same reason.

- I changed the angle of the rake slightly to allow less tuck and more rollback.

- I extended the rake braces to nearly the tips of the rake teeth to help keep everything solid, especially with the thinner stock.

- I sloped the braces downward about 10 degrees to help shed dirt as the rake moves through the soil.

I think that since my tractor has limited lift and breakout strength, I should be OK with these changes. After spending a few weeks pushing out Yaupon with my standard bucket, I am confident that this will work fine. Only time will tell, though.

I'll post more pictures of the progress if you are interested.

Regards,

- Just Gary