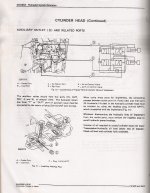

My 2002d has that same control valve and same looping hose that you have. I am assuming the headless plug you read about has been removed since the loop hose is there. My loader is tied in by cutting the high pressure line. The attached picture and instructions are out of a ym220/226 manual that is suppose to be the closest to my 2002d. I have often wondered if I could just use those outlets for a splitter or something. Don't need them so have never tried. I do have an outlet that comes out the right side (as you are looking at the picture) for a single acting cylinder that I use with a cement mixer. edit: One difference is the plugs shown in the drawing are listed as 3/4-16 but I believe the plugs on our grey market tractors are a metric size. For what that's worth.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loader plumbing

- Thread starter California

- Start date

- Views: 30227

More options

Who Replied?

/ Loader plumbing

#61

project_X

Gold Member

My 2002d has that same control valve and same looping hose that you have. I am assuming the headless plug you read about has been removed since the loop hose is there.

On my 1602D, a loop hose like the two of you have would indicate that the headless plug is installed.

If the headless plug is not there, you would be able to cap the block where the hose enters and exits, the flow would occur internally.

I believe that in order to add a rear remote in this configuration, remove the end of the hose connected to the block where it is stamped I and connect it to the input of the new valve. Take the pb out of the new valve and connect to the block where it says I. Take the tank port of the new valve and connect to the sump (I have a plug on the left side of my transmission case).

Here is my thread I wrote about on my 1602D

http://www.tractorbynet.com/forums/yanmar/217617-update-rear-remotes-complete-big.html

I now have a PB sleeve from Koyker, and will correct the plumbing when the time permits. My pump is only 3.3gpm, I'd like to upgrade it to a higher capacity at some point.