Im in the same boat. Mine would give me trouble so the other day I took it off only to fine that someone had welded some of the linkage. They also put a block of wood in the linkage to hold it in place. I have also taken my vavles apart only to find water in the hyd oil and trash in the vavles. So ive gotten those all cleaned up and will flush the hyd oil out. I also have some orings to replace. I ordered the manual and it is of very poor quality. I think i now how the linkage goes together but I realy think Im missing a spring. As I figure out more of this puzzle I will post it and maybe help you out. :confused2:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?

/ Long 445 3pt problem

#21

Hello,

yes I to found the manual of very poor quality. Im very disappointed.

Looking at the linkage there is a roller that slides between two "Jaws".

the roller is pushed by the draft control lever ( position control lever )

there is a spring that holds tension on the jaws to keep them together. It is a circular spring that holds tension inward.

I have tried every way to make the linkage work but none of the configurations I came up with work at. They always bind. My linkage is not bent but i just can get it figured out.

Im probably going to make my own linkage and I might just send the manual back. I paid 20 bucks for my cheap TSC manual for my IH and it is better than the manual for the Long.

Kody

yes I to found the manual of very poor quality. Im very disappointed.

Looking at the linkage there is a roller that slides between two "Jaws".

the roller is pushed by the draft control lever ( position control lever )

there is a spring that holds tension on the jaws to keep them together. It is a circular spring that holds tension inward.

I have tried every way to make the linkage work but none of the configurations I came up with work at. They always bind. My linkage is not bent but i just can get it figured out.

Im probably going to make my own linkage and I might just send the manual back. I paid 20 bucks for my cheap TSC manual for my IH and it is better than the manual for the Long.

Kody

AndrewInOz

New member

- Joined

- Aug 28, 2010

- Messages

- 22

- Tractor

- Same 90

You need the service manual. The closest I've found is

The Classic Machinery Network - Downloads - Fiat 480/500/540/640/DT workshop manual

which is for the Fiat original ( closely = UTB / Farmliner / Long / Oliver /etc)

U need log on and wait for admission, but the manual is good old style type.

PM me if u have problems with this. Sorry delay : we're preparing for harvest atm.

The Classic Machinery Network - Downloads - Fiat 480/500/540/640/DT workshop manual

which is for the Fiat original ( closely = UTB / Farmliner / Long / Oliver /etc)

U need log on and wait for admission, but the manual is good old style type.

PM me if u have problems with this. Sorry delay : we're preparing for harvest atm.

Hi guys,

I have a Farmliner/UTB 445 and having a similar issue, did this ever get resolved?

We bought a farm that came with this old tractor, front end loader and power steering work great. Came with a slasher fitted to the rear. We recently took it off so we could borrow a friends ripper or plow, but couldn't get the 3 point linkage to lift. I can lift it by hand but it slowly drops back down after I let it go, and I can push it down pretty easily.

Had a look in the manual and apparently there is 3 settings, was currently set to Float. I lifted the 3 point linkage by hand, raised the handlever to the top, and then while holding the linkage I moved the smaller handlever to the bottom position. Took a small amount of force to engage. It's stayed engaged but doesn't seem to work any differently. I suspect there is a stuffed valve somewhere, or the internal workings of the lever are out of whack.

I've attached a few photos, can anyone tell me what some of these other items with question marks do?

Thanks in advance

I have a Farmliner/UTB 445 and having a similar issue, did this ever get resolved?

We bought a farm that came with this old tractor, front end loader and power steering work great. Came with a slasher fitted to the rear. We recently took it off so we could borrow a friends ripper or plow, but couldn't get the 3 point linkage to lift. I can lift it by hand but it slowly drops back down after I let it go, and I can push it down pretty easily.

Had a look in the manual and apparently there is 3 settings, was currently set to Float. I lifted the 3 point linkage by hand, raised the handlever to the top, and then while holding the linkage I moved the smaller handlever to the bottom position. Took a small amount of force to engage. It's stayed engaged but doesn't seem to work any differently. I suspect there is a stuffed valve somewhere, or the internal workings of the lever are out of whack.

I've attached a few photos, can anyone tell me what some of these other items with question marks do?

Thanks in advance

Last edited:

UTBAmateur

New member

- Joined

- Jan 1, 2021

- Messages

- 1

- Tractor

- Universal 445

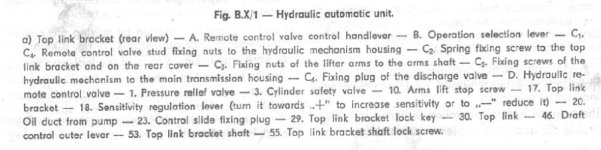

maybe this diagram helps.

its the sensitivity speed at which the hydraulics go up.

Awesome, cheers for the reply!

Ended up finding the right combination of levers to get the slasher to go up, only lifts a foot or so, but more than I need, and probably height limited by the length of the chains and other stuff down in that area.

Next trick is to find out where some of the disconnected wires go, but will start another thread.

fatdaddy37

New member

- Joined

- Jul 22, 2025

- Messages

- 2

- Tractor

- Long 445/Fiat

I have a Long 445 and recently (because of high weeds) ran the right wheels into a deep narrow wash. I had a shredder hooked up and was mowing. The front wheel dropped in first, hit hard and bounced out, then the rear wheel dropped in hard. After I got it out, I found that the hydraulic lift no longer worked. I could lift the arms all the way up (engine running), then they would very slowly drop to the bottom. On disassembly I found that the hydraulic piston was seized in about the middle of the sleeve. I replaced the sleeve, piston, o rings backup rings, and gasket. The lift works great again.