OP

lennyzx11

Veteran Member

- Joined

- Dec 20, 2015

- Messages

- 1,257

- Location

- Bennington Vermont

- Tractor

- Kubota L3301 HST/LA525 & 1964 Ford 2000 gas

"Can annular cutters be used for “half a hole” drilling?"

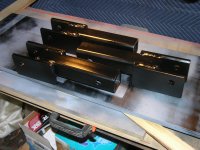

Lenny, I'm not sure about exactly half but I did "3/4 of a hole" for a mod to my flail mower's "float" linkage on the lower mounts - the bars are beefy enough I wasn't worried about weakening by effectively decreasing their width -

My thoughts on why I got away with it - the "more than half" that I cut kept the cutter from being able to easily jump to the side, so minimised any side loading (DEFINITELY a cutter killer)

I've not needed a "half or less" hole in anything yet, but I would think long and hard before trying it - anyway, "pics or it didn't happen" - plus, if you're gonna build a dedicated mag drill area I have a LOT more pics of the way I did mine, just ask if interested... Steve

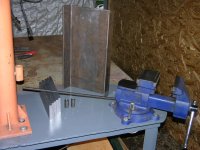

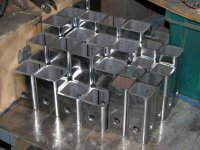

Pics 4 and 5 show one of my methods for ensuring that duplicate parts REALLY ARE - the table is a 12" piece of 10" C channel, overlaid with 1'2

[ plate for more magnetic pull. After welding the plate on I surfaced the whole thing on the mill for maximum magnet contact. Oh, and that vise is a reversible Wilton - haven't needed the extra jaw opening yet but if I do...

Steve, I like your setup. Thanks for the details. This is a lot better than the “metal plate with a hole in it that I was envisioning.

Can I get a picture of the back part of your stand?

I think you rest the front on top of the vise jaw and built legs on the back to hold it level but I’m guessing.

You mentioned milling. I confess that I’ve kinda watched for a mill used but have had no exposure to them and not sure I’d get the use out of one as it should be used with no training or exposure in my life. I see some amazing things created with them though.