boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,829

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

*rubs chin* i say go for mini ex.

on a different note, why not get a "generator" yep a generator, some tracks, and use electrical motors? 2 motors (one for left and right side tract) and then 1 more electrical motor on mower. and just mount generator on the tracks? with some variable speed motors, and some relays, to get to the remote. for wireless remote control. *shrugs* and, if you run out of juice on your wheel chair while out and about. plug the chair in.

wheel chair motors, i remember hearing being used a lot in the "robot wars" tv doing.

===================

i do not think mini ex is going to tear up yard any more than tracks from a tracked dumpster or tracked concrete buggy will tear up. it all comes down to how good you are at the controls.

also cutting the grass so it is a little bit higher, instead of scalping yard 1" long, keep it cut at around 3 to 5 inches tall. the thicker grass helps hide, the tear ups. *looks innocent* that and if you damage grass, it is not permanent. grass does grow back, 1 week to a couple months. all depends on how badly ya tore things up. and as long as you do not make ruts. everything will be fine, those ruts on other hand, are the ugly killer. a wider and longer track, will help prevent ruts. but at same time, make it a little more difficult in how fast you can turn. without causing a track to "slide" across the grass. as the other track moves.

mini ex and major tear up of grass = constant going back and forth, between say back yard to a dumpster at the street, and putting ruts in the yard. or picking up something heavy in the bucket and putting more weight on to the machine, and trying to drive machine across the yard with what ever is in the bucket / picked up by the backhoe.

removal of backhoe, and extra stuff should help reduce over all weight of a mini ex. (getting stripped down to bare essentials) would also help reduce over all machine weight, not to mention no one physically riding in / on the mini ex.

=================================

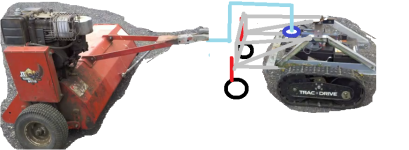

(see attached image)

on current machine, add 2 gauge wheels, you might find on regular finishing mower decks. to adjust height at what the deck cuts at, but use them as "wheelly bar" wheels. to help keep machine down. you might be able to pickup some "caster wheels" from local hardware store for cheap, but would most likely not last to long. without seizing up and bearings going out. hence gauge wheels from a finishing mower deck, that has stronger heavier duty bearings, in idea it would turn your little machine into kinda like a zero turn mower. but without the finishing mower mounted directly to the machine.

ay as goose neck hitch. should help lower things. and still allow the 360 degree spin on the machine.

================

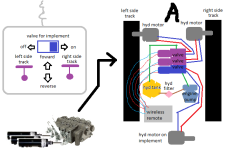

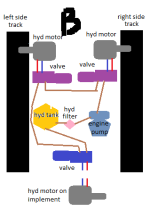

if you made your machine into a wider and longer unit, kinda like a zero turn mower. and placed a gas engine on it, with an alternator, to help keep a small battery charged.... you might be able to run a regular hydraulic pump right off the gas engine, and then use some valves, to control the 2 drive wheels errr 2 drive tracks. and then hydraulic hoses over to mower hyd motor. this might actually create a low profile machine ((does not stand up high)) it will just be long and wide in a sense. with a goose neck like hookup. for pulling things.

if ya go to zero turn setup, who says you actually need tracts? perhaps for better traction. being machine would be so light weight, but *shrugs*

on a different note, why not get a "generator" yep a generator, some tracks, and use electrical motors? 2 motors (one for left and right side tract) and then 1 more electrical motor on mower. and just mount generator on the tracks? with some variable speed motors, and some relays, to get to the remote. for wireless remote control. *shrugs* and, if you run out of juice on your wheel chair while out and about. plug the chair in.

wheel chair motors, i remember hearing being used a lot in the "robot wars" tv doing.

===================

i do not think mini ex is going to tear up yard any more than tracks from a tracked dumpster or tracked concrete buggy will tear up. it all comes down to how good you are at the controls.

also cutting the grass so it is a little bit higher, instead of scalping yard 1" long, keep it cut at around 3 to 5 inches tall. the thicker grass helps hide, the tear ups. *looks innocent* that and if you damage grass, it is not permanent. grass does grow back, 1 week to a couple months. all depends on how badly ya tore things up. and as long as you do not make ruts. everything will be fine, those ruts on other hand, are the ugly killer. a wider and longer track, will help prevent ruts. but at same time, make it a little more difficult in how fast you can turn. without causing a track to "slide" across the grass. as the other track moves.

mini ex and major tear up of grass = constant going back and forth, between say back yard to a dumpster at the street, and putting ruts in the yard. or picking up something heavy in the bucket and putting more weight on to the machine, and trying to drive machine across the yard with what ever is in the bucket / picked up by the backhoe.

removal of backhoe, and extra stuff should help reduce over all weight of a mini ex. (getting stripped down to bare essentials) would also help reduce over all machine weight, not to mention no one physically riding in / on the mini ex.

=================================

(see attached image)

on current machine, add 2 gauge wheels, you might find on regular finishing mower decks. to adjust height at what the deck cuts at, but use them as "wheelly bar" wheels. to help keep machine down. you might be able to pickup some "caster wheels" from local hardware store for cheap, but would most likely not last to long. without seizing up and bearings going out. hence gauge wheels from a finishing mower deck, that has stronger heavier duty bearings, in idea it would turn your little machine into kinda like a zero turn mower. but without the finishing mower mounted directly to the machine.

ay as goose neck hitch. should help lower things. and still allow the 360 degree spin on the machine.

================

if you made your machine into a wider and longer unit, kinda like a zero turn mower. and placed a gas engine on it, with an alternator, to help keep a small battery charged.... you might be able to run a regular hydraulic pump right off the gas engine, and then use some valves, to control the 2 drive wheels errr 2 drive tracks. and then hydraulic hoses over to mower hyd motor. this might actually create a low profile machine ((does not stand up high)) it will just be long and wide in a sense. with a goose neck like hookup. for pulling things.

if ya go to zero turn setup, who says you actually need tracts? perhaps for better traction. being machine would be so light weight, but *shrugs*