Graydin

Bronze Member

- Joined

- Dec 23, 2024

- Messages

- 51

- Tractor

- 3B

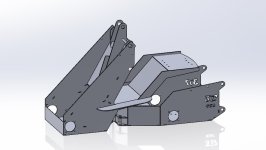

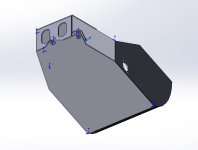

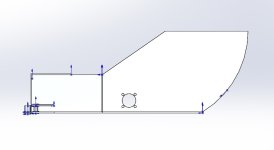

Greetings everyone! I want to show you how I build my front loader. I'll start with a bit of history: The design does not belong to me. My loader will be a combination of a general design idea that has been working for a long time and has proven to be reliable and well thought out, along with my personal modifications that I hope will make my loader even more convenient and reliable. The main goal is simplicity, affordability, easy and cheap repairs, and convenience when working with it.