MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 58,213

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

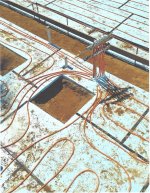

We repaired the three broken pipes and i dug three others just to be sure they were ok, since they were in the same area as the ones that broke. Get the gravel back in, packed it down and replaced insulation, taped tarp down to sides, put in wire and put back one run of pex. Two more runs of pex left but im out of daylight. So i piled rocks all over and i will be back next weekend it is supposed to be a rainy week so it would have been difficult for them to pour anyway. I will be able to get the pex installed and pressure test it next weekend.

The cement guy i am using will does fantastic work. I feel confident that he will get it done right.

Walls will be attatched with 5/8 j hooks holding 2x6 treated sill plates.

View attachment 550336View attachment 550337View attachment 550338

I've been considering putting PEX in our garage floor when we build it. Several websites say to do it exactly as you did, but the also say to set the wire mesh up off the foam or it won't be imbedded in the concrete and do little good as reinforcement. They suggest getting the bricks with the holes in them, and cracking them with a hammer to make chairs for the mesh to sit up on.

You might want to discuss that with your concrete guy.