SUCCESS....maybe?

Here's the update. First, a huge THANK YOU for all the safety information and concerns. I took every precaution into consideration.

JC, you were referring to the type of front loader and I found out some more information from my mother-in-law. My in-laws were the second owners of this tractor which they bought back in the 80s. Originally it did not have a front loader and the original owner, who was an older, DYI'er found this front loader and attached it himself. I attached a photo with arrows pointing to the attach points. Different color, not factory front loader, as I understand.

I had to move the assembly back approximately 2" and down about 1 1/2". I attached all the hoses, put an old oil filter on(smaller and might get demolished), and added oil since running it last. Started the tractor and with the front loader on the ground, used the hydraulics to pivot the assembly. I also put the tractor in gear and nudged it forward an inch or so and with some more finessing of the hydraulics, behold, I actually got a hole or two to somewhat line up. Add in some adjustments with a jack and here we go.

A little give and take and finally we have a bolt attached, holding the assembly somewhat in place.

I did the same on the left side and was able to get two in place.

So far, better than before.

And now - First Issue:

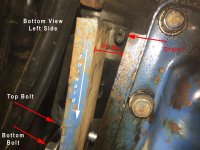

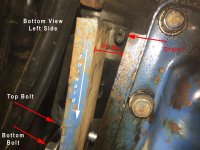

Left side, assembly bent from the frame. I'm calling the bolts the first two, top/bottom, under the gas tank. It's bent out, away from the frame.

The 12mm and 14mm are threaded before they get to the frame. While a slow and tedious undertaking, I can see once I get the other holes lined up, slowly adding washers to slowly bend that back in place... Well that's my Rabbit Hole comparison. The assembly holes are threaded, and the frame holes seem to be shallow. Which is an issue.

The other holes are slightly off, but can be managed.

All thoughts welcome!