Next Steps Complete!

I would say I'm about 70% of the 90% I'm striving for. I'll never have it at 100%!!

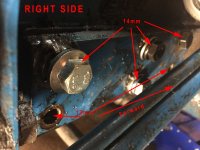

Right Side:

I was able to work some of the other bolts in. I have them tight, but not torqued down or with locktight. Right side 5 of 6 are in. They all need to be readdressed. #2 I'll try and get something in there, but very little to work with in the engine block hole. Looks like they may have tried to weld the bolt in.

#3 is a weird situation. The bolt hole on the block is about 1/8th of an inch too forward. I have a 12mm bolt in there and it tightens, but it probably should be a 14mm. #5 is rather difficult to get to, but I need a longer bolt to be able to add lock washer and washer to it.

Left Side:

All are fairly snug. #2 is barely hanging on. It's 12mm and not much to thread into.

Got them all tightened and decided to do a test that would lead to my next thing on today's list - The HOOD!

Loader up! And once back down on the ground all bolts were in place and tight and no slippage of the assembly

Radiator in right place

Hood Attaches Correctly!!

I'll make some minor adjustments to the bolts, place locktight and talk to the welder. Other than that, we're looking good!

Except for this!

If you all think it's best that I make a separate thread for dealing with this, I'll gladly do it. Looking forward to your feedback!

Thanks!!