whodat90 said:

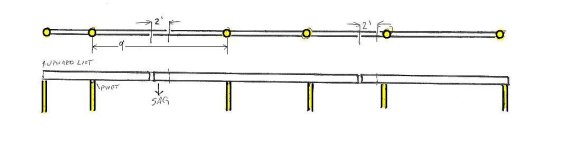

The beam that rests between the posts and the rafters is made of two 2x8s laminated together. They are not 40' long, so they had to be laminated together out of shorter stock, staggering the joints side to side. The overlap where the joints lie is only 2'. It seems to me that the overlap should be as large as posssible, and that the overlap portion or one of the joints should rest on top of one of the posts. They didn't do this, and it's starting to sag.

I'm still confused on the posts, but I'll have to see the pics to fully comprehend what you did.

When you say the 2x8's are laminated together, is that the same as nailing/screwing two of them togehter on the flat sides to make a beam that is 3 inches wide?

Did they put plywood between the two boards?

If the did not put plywood between them, it won't matter where the spacing is, it will sag. Half inch plwood ripped to the same width of the boards and sandwiched between them will add tremendous strenght to the beam, and it will prefent it from sagging. 2 feet is plenty of overlap for all three pieces when done this way.

Before glulams were so common, that's how most garaged door headers were built.

If it was me, I'd jack up the beam to make it level or even give it a slight arch. Then I'd rip some half inch plywood to the height of your beam. Most 2x8's are just over 7 inches, but they all seem to vary about a quarter inch. Attach the plywood to the inside of the beam with liquid nails and screws with at least 2 feet of overlap. Then I'd put another 2x8 over the plywood with liquid nails and screws with another 2 feet of overlap and not where the beam overlaps on the otherside of the plywood.

If you did use plywood, then it's sagging because it wasn't connected together with enough nails/screws and glue.

If you did all these things and it's done right, and your still sagging, then the beam is way too small. I think that the 2x8's are probably OK for strength over a 9 foot span. How far apart are the other posts? How much weight is resting on them? It's just the roof right?

Eddie