crash325

Elite Member

Nice use of acquired inventory! (scrap steel)

I noticed the mention you were going to grind off the galvanized coating where the welding was going to be done, and thought I might add a little "safety police" statement.

Hot dipped galvanize is not a coating, but rather a process that allows zinc to chemically bond with the existing steel, forming several layers of protection. This process is hard to remove without actually removing all of the layers, which if done correctly is significant in the amount of steel you have to remove. The more you remove, the better your welds are going to look, giving you the feeling that you must have gotten it all. Since I build most of my projects from the same source as you, I can't say "don't do it", but prefer to mention that zinc posioning is nasty and that even though you ground off the galvanized coating, you really aren't getting all of it.

SO..., whenever welding, cutting, or subjecting galvanized metal to any sort of heat, be sure to have good ventilation, even if you are welding outside. Those fumes in large amounts will make you sick really quick, and in smaller doses, make you sick in the long run.

Rant off, just trying to make sure everyone is aware...

David from jax

Hi David,

You bring up a good point on zinc. I try not to use galvanized unless that is all I have. Well aware of the poison, have had it once. Drinking lots of milk helps get rid of it.

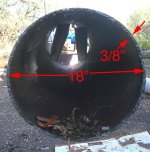

On this build nothing galvanized was used. It is also one of the reasons that I'm hoping to find another tank and not use the big one shown in early posts.

On things like pipe and square tubing, even though its ground off the outside, it still blows through from the inside. Crappy welds and the poison factor.

Hope everyone that welds reads this and heeds the warning.

Thank You,

Jim