crash325

Elite Member

Progress is slow - But some progress is better than none.

Some of these posts are a little boring, Sorry. Main reason for the reports is to help some of you that may be thinking of building something similar. When all done with the projects a Do & Don't Do will be posted at the end.

Used the torch to clean up the 2 holes for axle & water fill port. Ground all the zinc off the pipe coupling, had a nice snug fit. Just a little hammering and in it went. Welding went pretty well, a little build up where the welds overlapped.

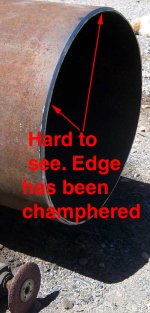

Once a fairly square and straight line was made, time to cut. Just as I was getting the torch out, a thought came to me. Why not try the angle grinder with a slitting disk. A lot slower than the torch, but a nice clean cut that does not need to be ground down. That worked out pretty well, slow, clean cut and almost no grinding. Wanting a good angle on the end spent quite a while grinding that. Sure did make me want a 7" grinder.

Cutting the end off the pipe took 2 slitting disks. HF cheepies. Grinding was 1, 24 grit sanding disk and it is still useable. The sanding disk is a lot faster than a grinding wheel and lasts almost as long.

A little more on Weight. My crummy math has come up with 434 pounds of pipe weight and 27 pounds for the end plates. AM I CLOSE???

Some of these posts are a little boring, Sorry. Main reason for the reports is to help some of you that may be thinking of building something similar. When all done with the projects a Do & Don't Do will be posted at the end.

Used the torch to clean up the 2 holes for axle & water fill port. Ground all the zinc off the pipe coupling, had a nice snug fit. Just a little hammering and in it went. Welding went pretty well, a little build up where the welds overlapped.

Once a fairly square and straight line was made, time to cut. Just as I was getting the torch out, a thought came to me. Why not try the angle grinder with a slitting disk. A lot slower than the torch, but a nice clean cut that does not need to be ground down. That worked out pretty well, slow, clean cut and almost no grinding. Wanting a good angle on the end spent quite a while grinding that. Sure did make me want a 7" grinder.

Cutting the end off the pipe took 2 slitting disks. HF cheepies. Grinding was 1, 24 grit sanding disk and it is still useable. The sanding disk is a lot faster than a grinding wheel and lasts almost as long.

A little more on Weight. My crummy math has come up with 434 pounds of pipe weight and 27 pounds for the end plates. AM I CLOSE???