ponytug

Super Member

These threads might help, as there are lots of detailed drawings;

www.tractorbynet.com

www.tractorbynet.com

www.tractorbynet.com

www.tractorbynet.com

If in doubt, you can search for "Bob tach" "specification" on your favorite search engine.

All the best,

Peter

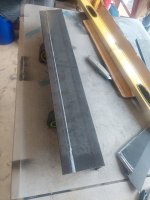

Tractor side SS quick attach build

I have been working on this for a while and recently started the actual fabrication work. I have a Montana with their style of QA (sliding pins) and it works ok but I find that it makes a sloppy connection. It's also not compatable with any others. My dad also recently purchased a 'bota L3400...

Are Bob Tech and SSQA the same?

New to the SSQA world. Looking at a grapple bucket that came off a Bobcat 943 for my NH WM 70. Owner says it’s Bob Tech but that it won’t fit my SSQA. I‘ve seen a bit on the net saying that Bobcat developed the Bob Tech standard and the it was adopted by other manufacturers and sold as SSQA...

If in doubt, you can search for "Bob tach" "specification" on your favorite search engine.

All the best,

Peter