You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Seeking advice on welding hook to FEL bucket

- Thread starter Captain Dirty

- Start date

- Views: 23923

/ Seeking advice on welding hook to FEL bucket

#51

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,753

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Richard, if your "45%" setting is actually 45% of 250 amps, you're about 25% too LOW on amps - have you "calibrated" your wire speed settings to know what IPM you're ACTUALLY running?

Wuz gonna post a link, but it looks like Jody's video on "calibration" isn't available - basically pick a knob setting, pull the trigger for 6 seconds, measure the length of wire (not actually welding of course), multiply by 10, write it down, change setting, repeat til you have a CHART... otherwise you're more or less just flying blind.

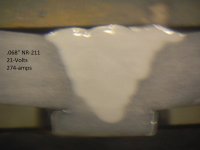

That weld looks like it's just laying on TOP of the steel to me - if it were mine, I'd turn up the heat and concentrate on PUSH angle, short stickout and staying at the FRONT of the puddle - admittedly, if Carl has only been welding a few weeks then I've been at it (MIG anyway) for SECONDS (about 5 years real time) -

But, thanks (in part) to Jody @ weldingtipsand tricks, so far nothing I've built has broke (my "break test" is build it, abuse it, fix whatever broke and/or add bracing ...Steve

...Steve

Wuz gonna post a link, but it looks like Jody's video on "calibration" isn't available - basically pick a knob setting, pull the trigger for 6 seconds, measure the length of wire (not actually welding of course), multiply by 10, write it down, change setting, repeat til you have a CHART... otherwise you're more or less just flying blind.

That weld looks like it's just laying on TOP of the steel to me - if it were mine, I'd turn up the heat and concentrate on PUSH angle, short stickout and staying at the FRONT of the puddle - admittedly, if Carl has only been welding a few weeks then I've been at it (MIG anyway) for SECONDS (about 5 years real time) -

But, thanks (in part) to Jody @ weldingtipsand tricks, so far nothing I've built has broke (my "break test" is build it, abuse it, fix whatever broke and/or add bracing

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 32,246

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Thank you guys very much for the tips.

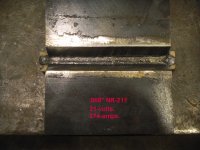

By SA's standards I've been running my voltage too low and my wire speed too high. Using his recommended settings I saw an improvement. I sped up the wire a tad and saw better penetration. I'll work on this and see what works the best for me. My tendancies are to go too fast.

I've not had any bead failures. I've torn tabs off flat surfaces in the past, weld didn't fail, metal did.

I'll play with the calibration method offered by Steve and see where my Welder is actually functioning at.

What I meant by my percentage reading was the wire speed on my Miller welder indicates the percentage of maximum wire speed available. If it's on "50" it's running 50% of the Welder's wire speed which is 670 IPM.

I've kept the link to the charts provided by SA.

Thank you guys for the education. Now if I can just retain some of it!!!!

By SA's standards I've been running my voltage too low and my wire speed too high. Using his recommended settings I saw an improvement. I sped up the wire a tad and saw better penetration. I'll work on this and see what works the best for me. My tendancies are to go too fast.

I've not had any bead failures. I've torn tabs off flat surfaces in the past, weld didn't fail, metal did.

I'll play with the calibration method offered by Steve and see where my Welder is actually functioning at.

What I meant by my percentage reading was the wire speed on my Miller welder indicates the percentage of maximum wire speed available. If it's on "50" it's running 50% of the Welder's wire speed which is 670 IPM.

I've kept the link to the charts provided by SA.

Thank you guys for the education. Now if I can just retain some of it!!!!

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 32,246

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

My Miller 250 MIG welder is rated at 670 IPM maximum wire speed.

My wire speed scale uses 0-100. 100 being 100% speed, or 670 IPM. It doesn't live up to the rating.

100 wire speed = 560 IPM

50 wire speed = 255 IPM

45 wire speed = 230 IPM (This is the wire speed I normally use)

I normally run the voltage at 21V. So according to SA's suggestions I was running the voltage too low. Was actually pretty close to the correct wire speed.

I'll play with this new found information and post my results.

I live no fantasy of being able to make my welds as uniform as SA does.

One question, do you guys push your wire or pull it?? I push it. I sweep across the bead in this pattern if working left to right (

My wire speed scale uses 0-100. 100 being 100% speed, or 670 IPM. It doesn't live up to the rating.

100 wire speed = 560 IPM

50 wire speed = 255 IPM

45 wire speed = 230 IPM (This is the wire speed I normally use)

I normally run the voltage at 21V. So according to SA's suggestions I was running the voltage too low. Was actually pretty close to the correct wire speed.

I'll play with this new found information and post my results.

I live no fantasy of being able to make my welds as uniform as SA does.

One question, do you guys push your wire or pull it?? I push it. I sweep across the bead in this pattern if working left to right (

Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 6,874

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

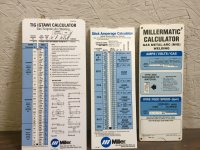

Richard, my wire speed dial is set up similar to yours.

I recommend using Steve BukitCase's Jody's Welding Tips and Tricks (whew) method to get ACTUAL "inch per minute".

And if you don't already have these--

--I'd highly recommend them. They're available on eBay but I'm quite certain I got the set shipped for FREE from Miller.

Terry

I recommend using Steve BukitCase's Jody's Welding Tips and Tricks (whew) method to get ACTUAL "inch per minute".

And if you don't already have these--

--I'd highly recommend them. They're available on eBay but I'm quite certain I got the set shipped for FREE from Miller.

Terry

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,753

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Old saying - "if it's Slag, you Drag" - so push unless you're doing flux core - also, when weaving I have to concentrate pretty good to NOT get too long a stickout in the middle. If I can see the puddle TOO good, it usually means I forgot

Shield Arc

Super Member

If you are right handed. Hold the Mig gun in your right hand. Start your weld on the right, and travel to your left, (push). Anything that produces slag, start on the left, and travel to your right, (drag).

99.9 % of the time I do a little up & down motion, or a little side to side motion.

99.9 % of the time I do a little up & down motion, or a little side to side motion.

Attachments

k0ua

Epic Contributor

Richard, my wire speed dial is set up similar to yours.

View attachment 492108

I recommend using Steve BukitCase's Jody's Welding Tips and Tricks (whew) method to get ACTUAL "inch per minute".

And if you don't already have these--

View attachment 492109

--I'd highly recommend them. They're available on eBay but I'm quite certain I got the set shipped for FREE from Miller.

Terry

There is an ap for that to run on your smartphone. I have it on my android based smartphone, but I am sure it is available for iPhone too. or you can use your PC to get it too.

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 32,246

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Richard, my wire speed dial is set up similar to yours.

View attachment 492108

I recommend using Steve BukitCase's Jody's Welding Tips and Tricks (whew) method to get ACTUAL "inch per minute".

And if you don't already have these--

View attachment 492109

--I'd highly recommend them. They're available on eBay but I'm quite certain I got the set shipped for FREE from Miller.

Terry

Yep, looks similar.

I used SA's link and made myself a handwritten chart for the basic stuff I work with and taped it to the Welder.

Those calculators would be very handy. Next time in the local Airgas store I'll see if they have any. Thanks!!!!

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 32,246

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

I am left handed and go left to right.

I played with the settings a little this afternoon. My welds "smoothed" a lot. I've been running my voltage a little too low and my wire speed a lot to slow. I'm building a fire now which smooths the welds.

I'm never too old or smart to learn something. I've welded for 50 years. My welds will now be stronger and "prettier".

I remember my AG teacher in High School saying "a pretty weld is a strong weld". Something to that.

I played with the settings a little this afternoon. My welds "smoothed" a lot. I've been running my voltage a little too low and my wire speed a lot to slow. I'm building a fire now which smooths the welds.

I'm never too old or smart to learn something. I've welded for 50 years. My welds will now be stronger and "prettier".

I remember my AG teacher in High School saying "a pretty weld is a strong weld". Something to that.