3Lfarms

Platinum Member

I am in the planning stages of a barn I want to build. The purpose of the building is to eventually be a hay barn for a small cattle ranch and homestead. In the shorter term, the containers will store our belongings while we build a house on the property and be a place to park our 43’ fifth wheel.

I am not in the city limits, just the county to deal with and it is very rural. It’s not in the middle of nowhere, but you can see it from there. Since it will be considered AG, I do not expect any permit issues, but I want it to last at least 75 years.

I want to set both containers on poured footings and piers. Frost depth is 30”. I am planning on digging down 36” and pouring 24”x24” footings with rebar and then setting sonotubes on them, then backfill and fill the tubes to 6” above grade. My soil is 24” of hard clay on top of a mix of sand and clay. It’s very dry here, but it does get down to about -25f in the winter.

The containers would then be secured to the piers to prevent any movement.

My main question is since I intend to put a large roof across these, do they need footings other than at the 4 corners of each container? I saw a show on TV where they built a house out of shipping containers, and they poured 4 footings on each side of the container so it sat on 8 rather large footings. I know the containers are designed to only be supported by the 4 corners, but if it has to support a roof structure, would it be that much better?

Once the containers are in place, I intend to add 5’ or so of poles or beams to raise the the height of the trusses over the center part of the barn. This is where I do not know which method would be both strong and economical. I could weld short vertical beams on top of the containers to give me the height I want and brace them adequately with a beam running the length of the containers to support the roof trusses. Any ideas on how to do this are welcome.

I plan to work with a truss company to figure out the design and sizing of the roof trusses, I’m not willing to risk building those myself.

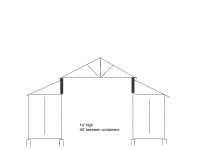

Here is a sketch I drew up to help illustrate my plan so far. I am planning on the two lean-to style roofs that are separate from the main span to give ventilation for hay and keep the top of the containers dry.

I am not set on the dimensions. I am planning on using 40’ containers, but have the main roof section over hang in front and back by 3 or 4 feet to make the total length 46 or 48 feet long to keep my trailer dry.

I imagine some dimensions are more economical than others on truss width, so the dimensions may change once I decide on what I am willing to pay.

I think this plan gives me enough storage, is something two guys and a 70hp tractor can build, and is good bang for the buck.

What am I not thinking of?

I am not in the city limits, just the county to deal with and it is very rural. It’s not in the middle of nowhere, but you can see it from there. Since it will be considered AG, I do not expect any permit issues, but I want it to last at least 75 years.

I want to set both containers on poured footings and piers. Frost depth is 30”. I am planning on digging down 36” and pouring 24”x24” footings with rebar and then setting sonotubes on them, then backfill and fill the tubes to 6” above grade. My soil is 24” of hard clay on top of a mix of sand and clay. It’s very dry here, but it does get down to about -25f in the winter.

The containers would then be secured to the piers to prevent any movement.

My main question is since I intend to put a large roof across these, do they need footings other than at the 4 corners of each container? I saw a show on TV where they built a house out of shipping containers, and they poured 4 footings on each side of the container so it sat on 8 rather large footings. I know the containers are designed to only be supported by the 4 corners, but if it has to support a roof structure, would it be that much better?

Once the containers are in place, I intend to add 5’ or so of poles or beams to raise the the height of the trusses over the center part of the barn. This is where I do not know which method would be both strong and economical. I could weld short vertical beams on top of the containers to give me the height I want and brace them adequately with a beam running the length of the containers to support the roof trusses. Any ideas on how to do this are welcome.

I plan to work with a truss company to figure out the design and sizing of the roof trusses, I’m not willing to risk building those myself.

Here is a sketch I drew up to help illustrate my plan so far. I am planning on the two lean-to style roofs that are separate from the main span to give ventilation for hay and keep the top of the containers dry.

I am not set on the dimensions. I am planning on using 40’ containers, but have the main roof section over hang in front and back by 3 or 4 feet to make the total length 46 or 48 feet long to keep my trailer dry.

I imagine some dimensions are more economical than others on truss width, so the dimensions may change once I decide on what I am willing to pay.

I think this plan gives me enough storage, is something two guys and a 70hp tractor can build, and is good bang for the buck.

What am I not thinking of?