4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,096

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

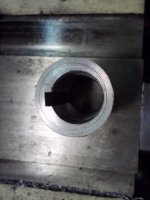

I almost always use my 4 jaw. My self 3 jaw is a piece of crap and runs about 15 thousands out of true. Besides I like to challenge myself and see how true I can get something to run in the 4 jaw.Looking real good! Always fun to whip out the 4 jaw. As for keeping it domestic: not everyone's got 10K for a lathe and mill either. Or the 5K in subsequent tooling to make them useful.I live to make stuff. I don't want to buy it if I can build it.