I have a Woods TSC50 grinder on the 3 pt.

It shakes, it SHAKES the tractor, even with its ground frame planted firmly.

I forget how many teeth are on it, but they are left right and center.

3 teeth in the cut rule ? Fine for when you know what the "cut" is,

In reality you will strike voids as you chew through stumps of trees that have rotted from the inside out - often the reason the stump is THERE to be ground.

Then just ABOVE grade you hit rocks - and you WILL want to grind a bit below grade.

They either get pulled up as the tree grows, or the roots form around them, not sure which but they ARE THERE and your wheel WILL hit them.

Then the tractor jumps and if you hook a rock the clutch MIGHT slip, or the tractor might stall.

Ahhh, that response was from reading only a few of the early replies - with the 2 tooth wheel thing.

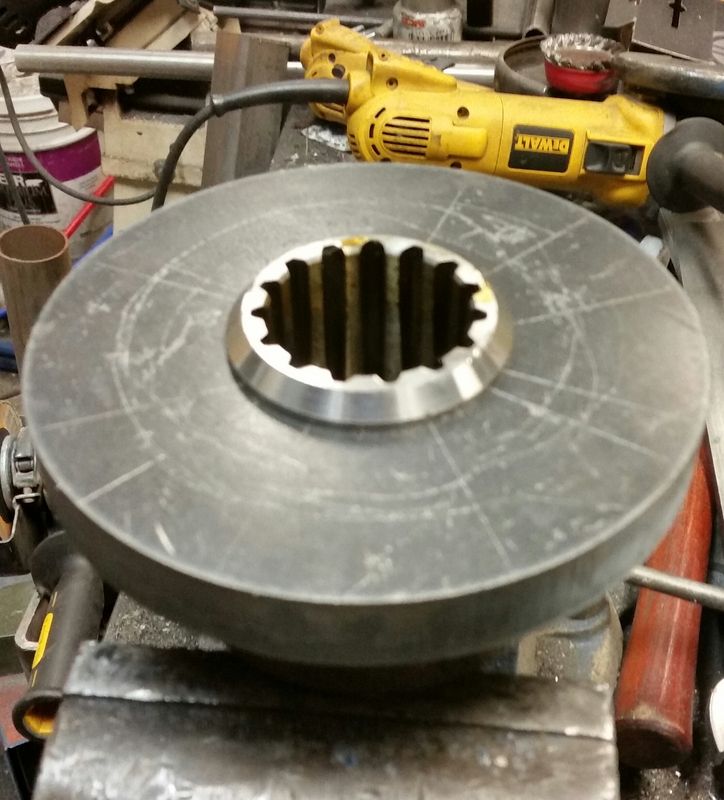

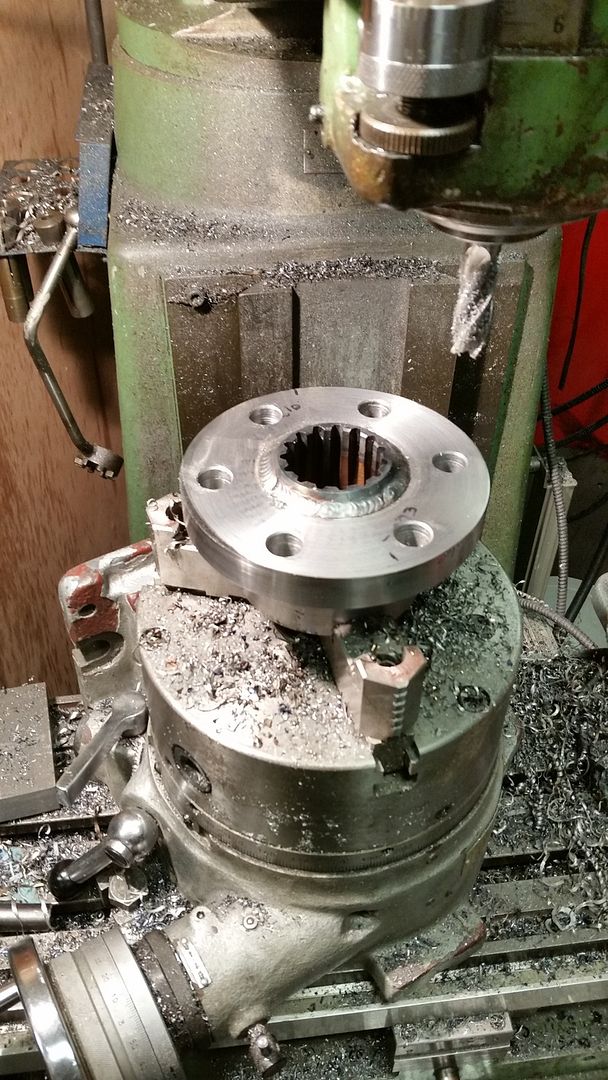

Pleased to see you went for a LOT of teeth in various rows.

Be very careful when swinging while cutting, it is quite possible to quickly wear out a wheel from the sides - i.e. don't cut deep and "plane" the stump with the side of the wheel.