OP

Jim Timber

Veteran Member

Those of course started as bar stock before being turned.

Frame taking shape

Dry cut saw doing one thing it does really well

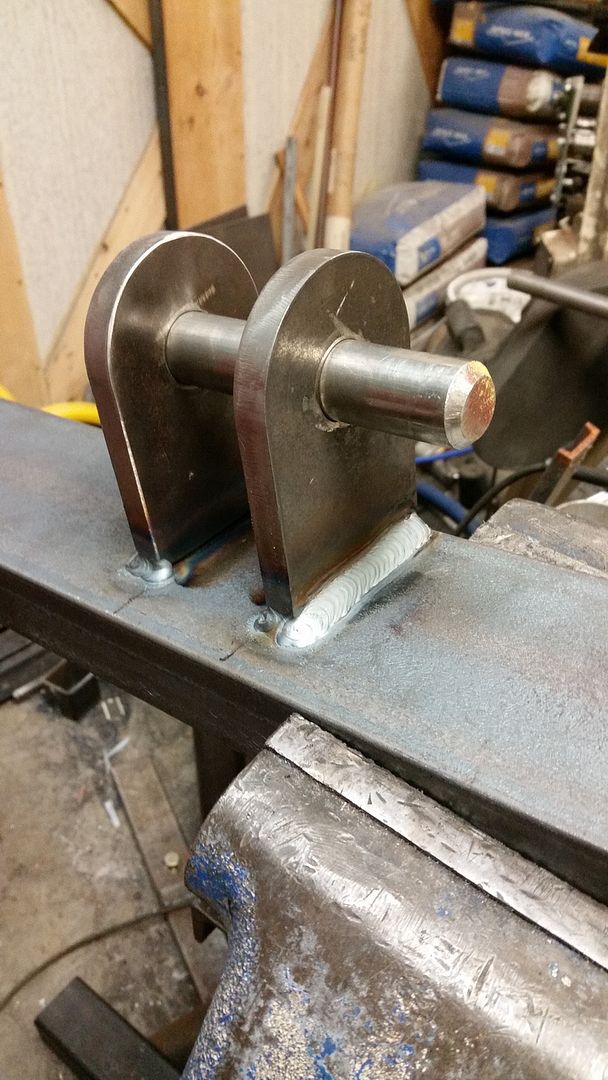

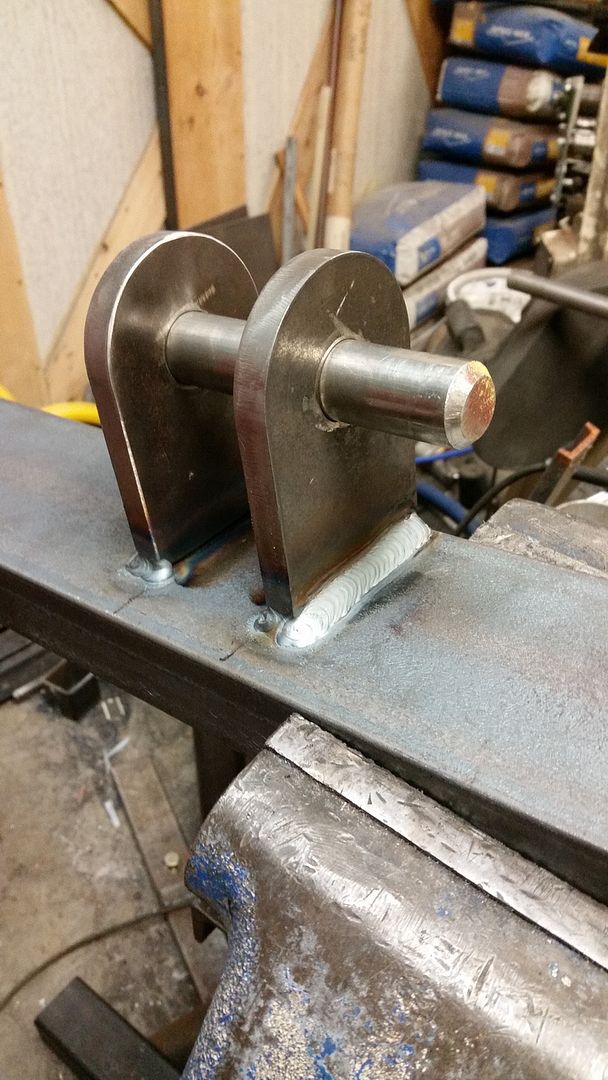

I use a temporary pin to hold things in alignment for welding

This is a different view of the hub flange before being assembled to the splined sleeve

That's pretty much it for build pics.

Frame taking shape

Dry cut saw doing one thing it does really well

I use a temporary pin to hold things in alignment for welding

This is a different view of the hub flange before being assembled to the splined sleeve

That's pretty much it for build pics.