ArtMech

Platinum Member

- Joined

- Oct 5, 2010

- Messages

- 952

- Location

- Lithuania, EU

- Tractor

- Present: 2003 Kubota M9000 DTF; 2001 Kubota B72. Sold: 1985 Kubota L2202

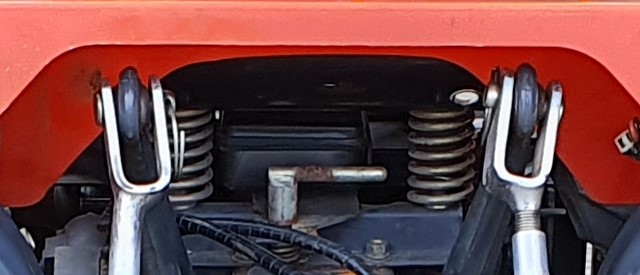

Installation of a 3 point hitch optional link on my new/old Kubota Granbia-boy GB-15.

I had to reweld the top ends of both lifting rods. Those were welded just straight. It was a need to make them under an angle.

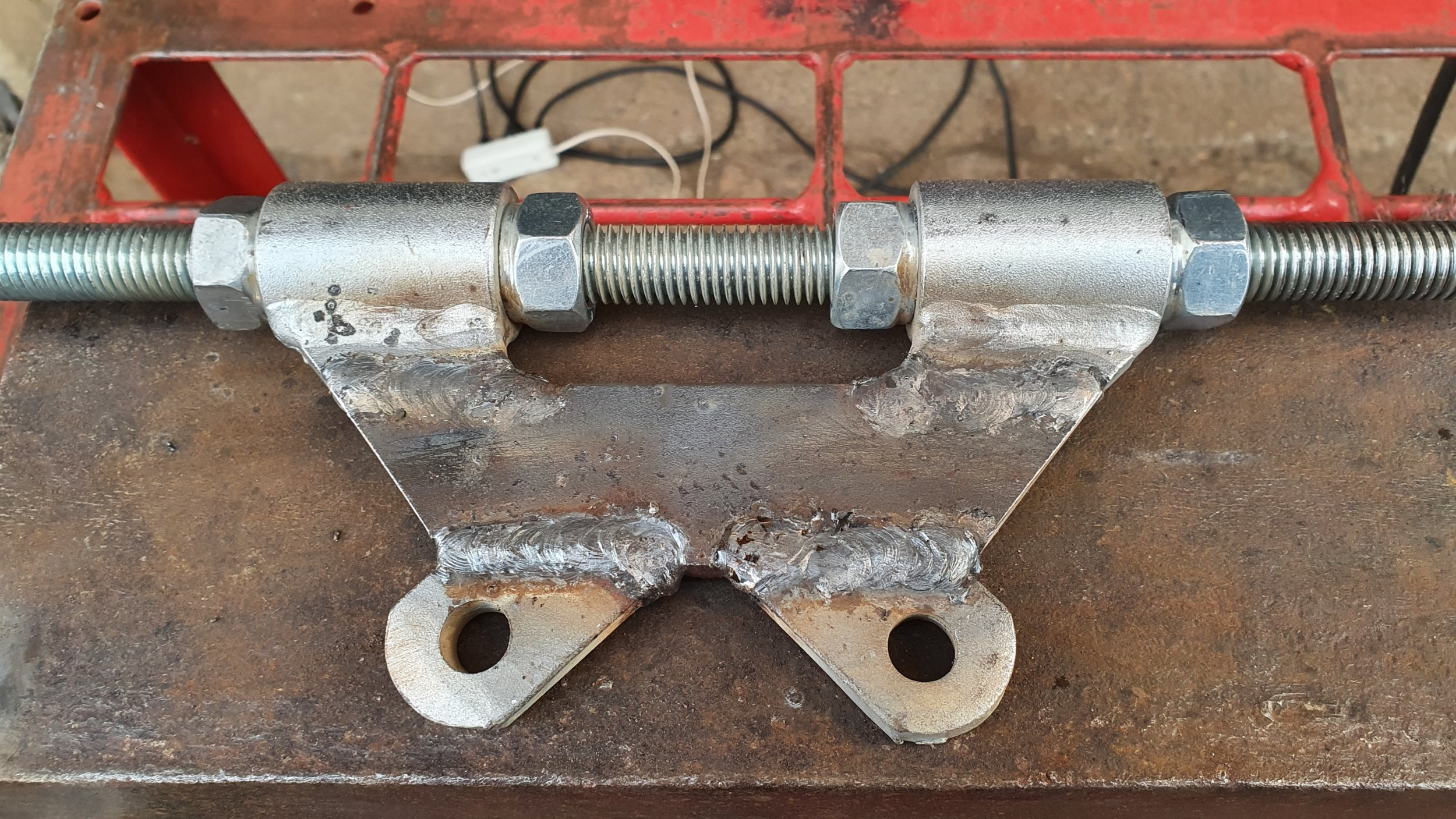

Another thing I didn't like was arrangement of the stabilizers. It was foreseen by a producer to mount them outwards. It looks not good to me. I decided to rearrange them to be mounted inwards.

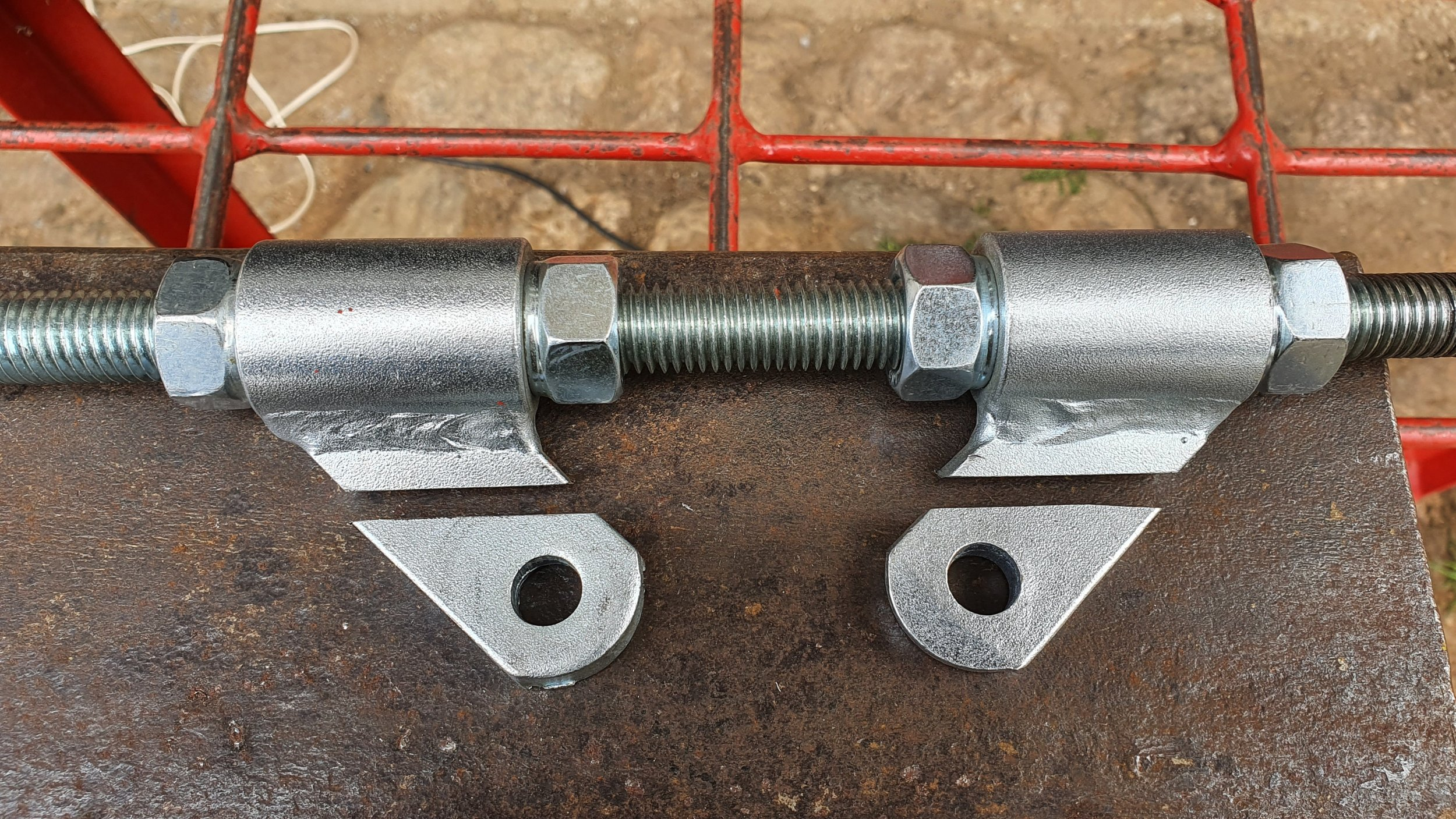

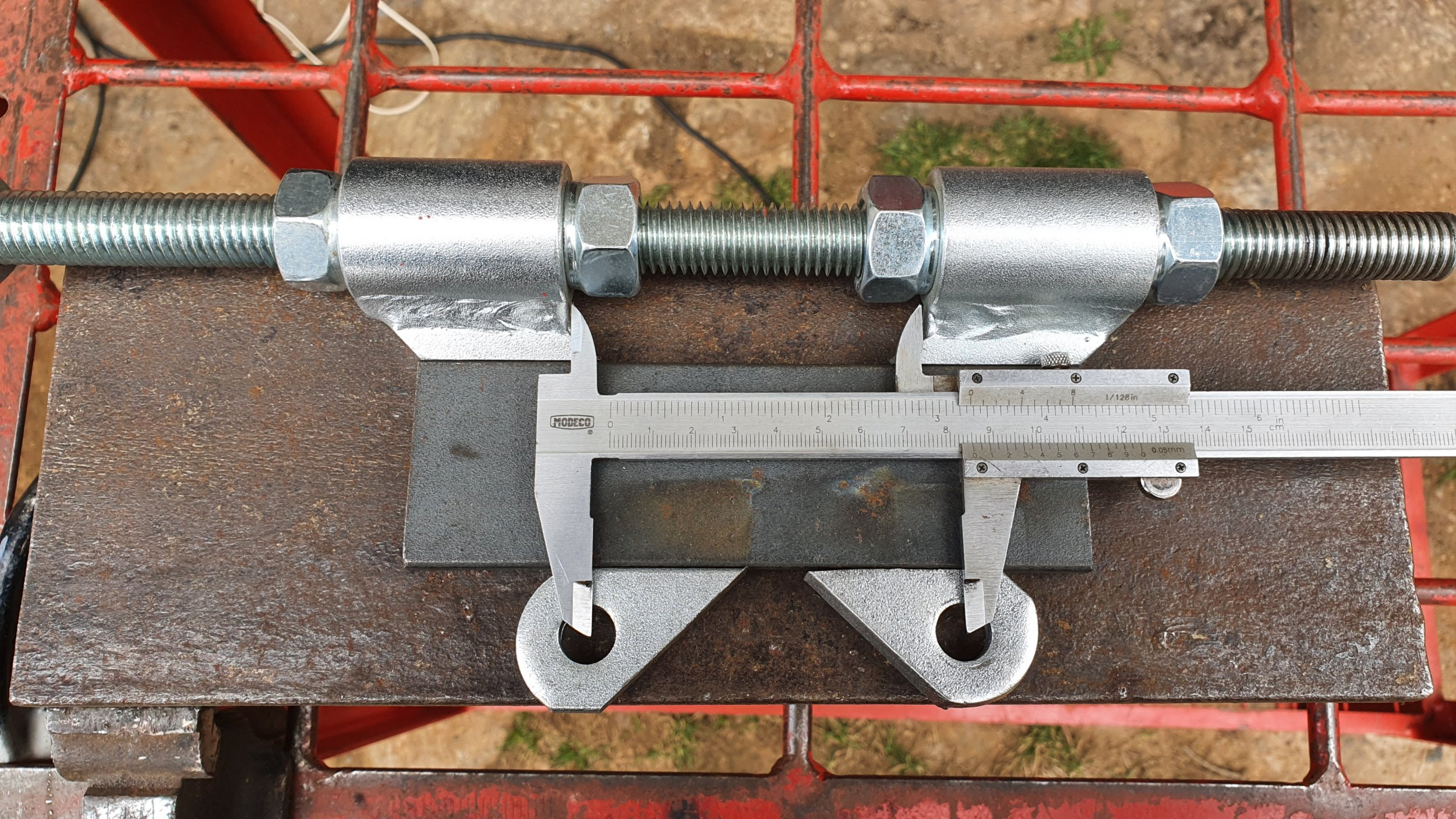

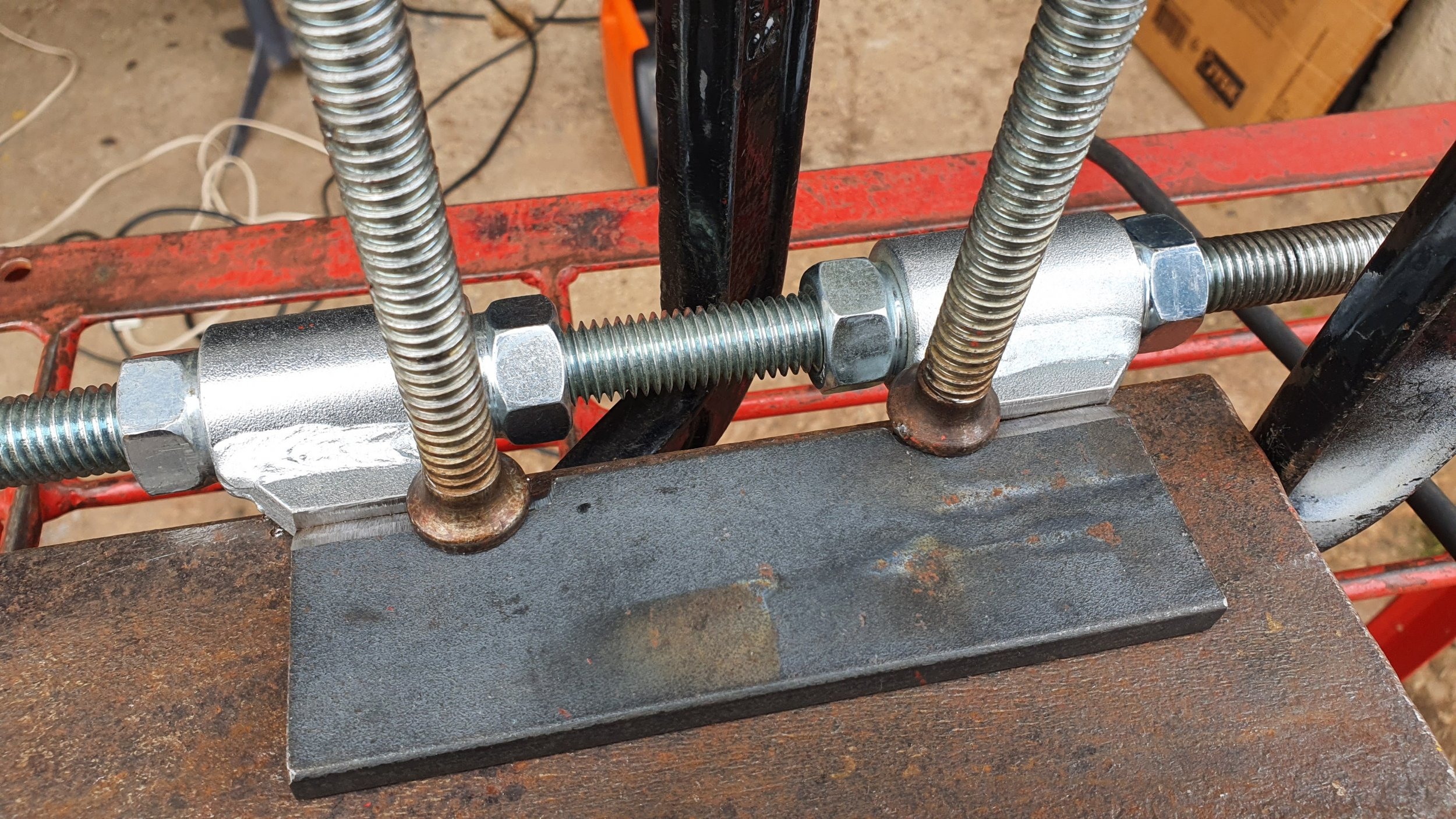

To do this I had to remake two factory brackets into the one. It had to be cut both brackets and to weld them with a steel strip in the different way.

The result looks funny, but hope it'll work well.

It was important to avoid possible touch of a bracket with a PTO shaft or its plastic cover.

After an axle of lower links was shortened it was avoided of being bent load created by the stabilizers.

I had to reweld the top ends of both lifting rods. Those were welded just straight. It was a need to make them under an angle.

Another thing I didn't like was arrangement of the stabilizers. It was foreseen by a producer to mount them outwards. It looks not good to me. I decided to rearrange them to be mounted inwards.

To do this I had to remake two factory brackets into the one. It had to be cut both brackets and to weld them with a steel strip in the different way.

The result looks funny, but hope it'll work well.

It was important to avoid possible touch of a bracket with a PTO shaft or its plastic cover.

After an axle of lower links was shortened it was avoided of being bent load created by the stabilizers.