ptsg

Super Member

I used to buy quite a few hydraulic stuff from them, specially hydraulic hoses since they had that "Build your own" tool and the prices were great. That was before Brexit of course and now the shipping went to the roof, plus I get hit hard at the customs here for some reason.That was great find, I think the original is a vapormatic, unfortunately spares no longer exist, that valve is fine its just the spool I need, such a pity,

Your are correct with your stab at the new spool manufacturer!!

I might keep looking and see what turns up on ebay, they have a sectional valve at £325 I thought I would try this first and was advised by a hydraulic engineering firm I send a request to help with refurbishment of the original spool to just get a monoblock spool, cheaper option to a repair.

Slice Valves - 1/2 BSP Ports | Directional Valves | Flowfit

View Our Range Of Slice Valves With 1/2 BSP Ports From Our Range Of Directional Valves. Incorporate Monoblock Control Valves Into Your System Today.www.flowfitonline.com

Chris

I wouldn't lose the faith on that new valve just yet. It's just not function quite right. It does look like it has a check valve, and it may be stuck open causing that effect you're experiencing. You may want to pull the check valve and see if it's moving freely, or something is preventing it from closing all the way.

Does it happen on the curl/dump circuit as well? I imagine it would be hard to tell and it may not have enough weight to recreate the same effect.

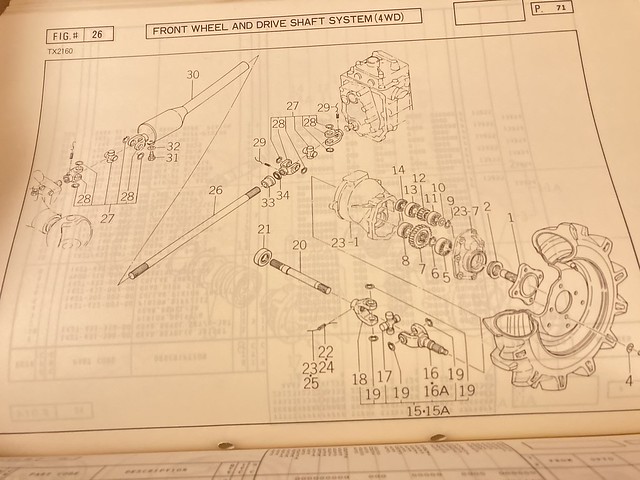

This should be it. I marked the location on the picture.

Untitled

Untitled Untitled

Untitled