weldingisfun

Veteran Member

- Joined

- Dec 12, 2006

- Messages

- 1,824

- Location

- West Bell County, Texas

- Tractor

- Mahindra 4500 4WD w/FEL, and Scotts S2048 lawn tractor

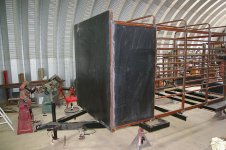

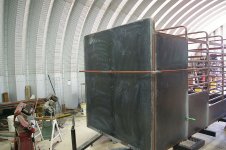

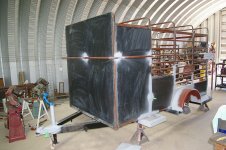

The rear gates were next. I have found that having the right gate wider than the left, I am right-handed, makes it easier to load goats by yourself. And, by having the interior gate open to the right side of the trailer allows you to get your goats in and then push them to the front of the trailer using the gate. Keeping the left side rear gate closed prevents the critters from slipping back past you.

The left gate serves as the anchor point. It is latched to the floor of the trailer and the right gate bumps up against it.

The latch can be secured with a lynch pin or a padlock. The padlock is for when you are transporting goats and stop for lunch. It keeps the Lookie-Lous from opening the gates and letting your goats out into the parking lot. There are some really stupid people in this world.

There are some really stupid people in this world.

The left gate serves as the anchor point. It is latched to the floor of the trailer and the right gate bumps up against it.

The latch can be secured with a lynch pin or a padlock. The padlock is for when you are transporting goats and stop for lunch. It keeps the Lookie-Lous from opening the gates and letting your goats out into the parking lot.

There are some really stupid people in this world.

There are some really stupid people in this world.