Gary Fowler

Super Star Member

- Joined

- Jun 23, 2008

- Messages

- 11,998

- Location

- Bismarck Arkansas

- Tractor

- 2009 Kubota RTV 900, 2009 Kubota B26 TLB & 2010 model LS P7010

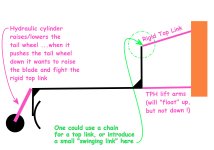

Candyman, I think you are going to have to hook up to that blade and take some photos. Maybe some before and after your friend welds the adapter plates on to show everyone the problem and the fix if it works. I dont think the top link distance will change a lot if you just drop straight down. The lift arms are on a circular tangent line and fartherest away from the tractor should be level, then get closer as you lower or raise from that point. Since you are lowering your arms to hook at the bottom of the possible lift the 3rd arm distance wont change. You will have to make sure that when you raise it all the way up, that it doesnt get into your tractor as the higher you lift it, the closer it is going to come> I know some of my implements get really close to the tires when raised as high as they go and you will be exceeding that by at least 8" looks like. Just watch closely when the first lift happens for tire to bar clearance. The other pinch point is going to be the 3rd arm watch closely as you come up to make sure it doesnt jam at the tractor or the implement since you will be raising much higher, I think you may find that you wont have clearance at the tractor and possible on the blade either. You could modify the blade but not the tractor so watch those three points.