Ole Orange

Bronze Member

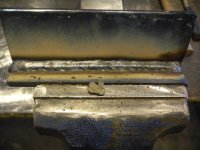

WOWI bought my first 5 lbs of 7014 and as in my first post I burned nothing but 6011 for years, I cant believe how easy it is its a dream to work with. THANK YOU everybody for all the help Where was Tractor by Net 30 years ago.

PS. used my 40 dollar Harbor freight auto dark helmet still working great.

PS. used my 40 dollar Harbor freight auto dark helmet still working great.