3Ts

Elite Member

I've seen high reading pressures from corroded gauges and pressure switch. Just like other posts, I'd start by replacing both and I'd bet the problem will be solved.

Pressure is pressure however if you have restricted flow pressure will still read without issue. I have replaced two 4” well pumps one from lightning strike and another from bad foot valve. Rule of thumb when you replace pump you change pressure switch. Relay contacts wear over time pressure can change. I run at 20/50 switch however I have large bladder tank to handle drop. Also bladder tanks go bad either rust or bladder failure. You can tell real quick on air input valve. If you press the center of the valve and water leaks the tank needs replaced. Ask your plumber these questions while he is there. I had to learn the hard way myself. I deal with fluid pressure every day in the liquid paint business. Pressure is pressure unless line is 100% plugged. Flow is completely different on restricted line pressure is constant. Hope you get your answers.So I have been worried my water pressure is too high in my house. If I can trust the pressure gauges ( one at entrance to 30 gal pressure tank and one near carbon and string filter setup) when well shuts off with the 20 /40 pressure switch at 40 psi, the well pump clearly can be heard to shut off, but the pressure gauges continue to rise and even out around 80 psi ( if I can trust the gauges) I got a new gould 240 volt submersible well pump 2 years ago that replaced a 20 yr old one, my well is 30 ft deep spring) I did try adjusting the two nuts on the pressure switch and now have it turning well pump on at around 15 psi , if I can trust gauges , and well pump shuts off at 40 psi, but pressure continues to rise to at least 75 psi. What do the well experts here think is going on ???

Thanks for all the advice, I decided to call local plumber, but now with advice here at TBN I am less likely to be led astray by any mischievous tradesman. At minimum I will have focus on him replace small piping with brass to new gauge and pressure switch and I have a new spare pressure switch already. Hopefully they return my voicemail this week with an appointment. I am going to see if I can find a pressure gauge tool that screws on to hosebib to give me a accurate read to calm my nerves in future. Meanwhile everytime I walk by pressure gauge in mechanical room and see it at 75 or 80 psi , I turn laundry tap on to relieve some pressure. ( but I swear it doesn't seem like 80 psi in faucets)

Pretty easy to see if the points in the pressure switch open up or not. If they are open, the pump should be off, but I would verify with an amp meter.Plumbers are here right now, they replaced gauge at tank, .....it still went high pressure, ....so tested with plumbers tool gauge at hise bib and it is a true 80 psi, not good, ....feels pressure switch could be not working right, so replacing that now......fittings were fairly clean fo both . .....will let uou know outcome.

Even without the ball valve to the pressure switch the nipple itself could clog. This happens all the time. You need a 75 PSI relief valve in place of boiler drain or on a 3/4 tee with the boiler drain. The relief should have been popping off long before your tank pressured up to really high pressure. I have seen the bottom blow off tanks like that, making it a rocket and going through the roof, taking some of the plumbing with it. Pressure relief valves are important.Mystery SOLVED !!! .....although you can't see it in my first picture yesterday ( hidden under old pressure switch) there was a small ball valve that the original house owner put in so he could easily isolate the pressure switch and the tee ed off gauge. That ball valve was severely constricted. So as can be seen by the pic attached , My plumber removed that little ball valve, and replaced with straight nipple to new pressure switch and repositioned new gauge over to the 1 in feed tee. . So now I have a new 30/ 50 psi switch, a new gauge and no feedback pressure. Well turns on at 30 psi and off at 50 psi and does not gradually increase further anymore. He did test the switch with amp meter and also emptied pressure tank and tested its psi at its shraeder valve ( no water pissed out at shraeder) It is 10 psi low so when I get chance I will get compressor and get it up to 28 psi like plumber suggested. Thanks everyone ! I think my urging my plumber about suggestions I got here helped us keep bill at only $600. And now I can do it on my own if ever again. View attachment 749299

The pressure tank I referred to and that is in pics is my well pressure tank, not a boiler pressure tank. But thanks for headsup......all is good.Even without the ball valve to the pressure switch the nipple itself could clog. This happens all the time. You need a 75 PSI relief valve in place of boiler drain or on a 3/4 tee with the boiler drain. The relief should have been popping off long before your tank pressured up to really high pressure. I have seen the bottom blow off tanks like that, making it a rocket and going through the roof, taking some of the plumbing with it. Pressure relief valves are important.

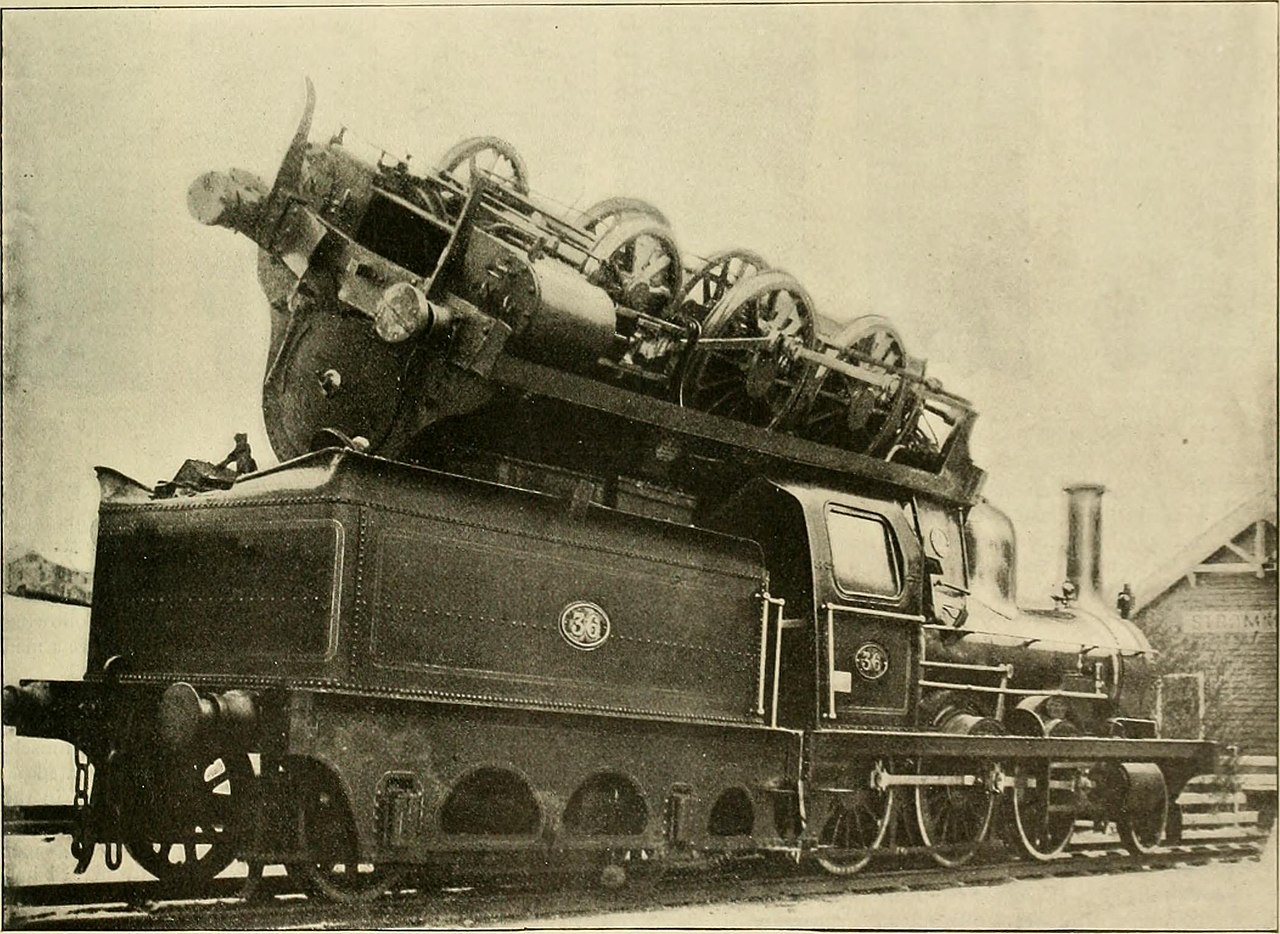

I know exactly what kind of tank you have. I have installed a few thousand of them and had a few wiz by my head when they blow up, like in the picture above. All is not good until you install a 75 PSI relief valve.The pressure tank I referred to and that is in pics is my well pressure tank, not a boiler pressure tank. But thanks for headsup......all is good.

Sorry you confused me when you reffered to boiler twice in your post. But it is all good. I am confident my plumber checked for all applicable pressure tank safe operation needs. Thanks for headsup.I know exactly what kind of tank you have. I have installed a few thousand of them and had a few wiz by my head when they blow up, like in the picture above. All is not good until you install a 75 PSI relief valve.

Hope your plumber has good insurance. Have a nice day!Sorry you confused me when you reffered to boiler twice in your post. But it is all good. I am confident my plumber checked for all applicable pressure tank safe operation needs. Thanks for headsup.

No problems.Thanks Egon. I never thought about my use of the word boiler drain instead of faucet would make someone think I was talking about a boiler tank. As you said any pressure tank should have a preset pressure relief valve for safety. I don't understand why someone wouldn't want a 10 dollar pressure relief valve to save their butt? It would have also made it much easier to diagnose the clogged nipple to the pressure switch because the pressure relief should have been popping off. I just assumed there was a pressure relief and started looking for other possible problems.

I think as long as the system has a pressure relief in it somewhere, you are in good hands. Most water heater tanks have a temperature/pressure relief on them. It is required for modern code compliance.Using the description “boiler drain” is generic for the type/design of the valve. They are usually a globe type valve so a specified drain value can be maintained.

Any pressure tank should have a preset pressure relief valve set at recommended pressure by vessel manufacturer.

www.eng-tips.com

www.eng-tips.com