I found this in the manual so it goes AGAINST all the bungee talk....

A Do not hold the lever in the "REARWARD" or "FORWARD" position once the remote cylinder has reached the end of the stroke, as this will cause oil to flow through the relief valve. Forcing oil through the relief valve for extended periods will overheat the oil.

A Whenusingthetractorhydraulicsystemtopowerfront loader, do not operate boom and bucket cylinders simultaneously.

NO, no it doesn't, again you are confusing apples and oranges. OF COURSE you would not hold a remote valve open when it is looking into a cylinder as the cylinder would fill with fluid, pressure would increase until the relief valve opens. If the relief valve did not open, then your hydraulic pump would explode, or "grenade" as sometimes said. THIS IS NOT the same thing as using a remote valve to send fluid to a backhoe held open with a bungee cord which will when the backhoe valves are closed will just send the fluid back to the reservoir. Pressure does not build in this scenario as the fluid has some place to go. Thru the valve in the backhoe and then back into the reservoir or also called the "tank" which is the transmission of your tractor.

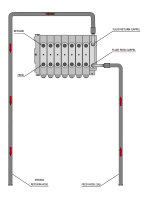

Lets start with the basics. Hydraulic pumps do not "make pressure" they "make flow". The hydraulic pump in your tractor is making a flow of hydraulic fluid, but when it comes out of the pump it does not have any appreciable pressure until it encounters something that resist the flow of fluid. The first thing it encounters on its journey back to the tank or reservoir is likely the FEL valve. Unless one of the valves on the loader is operated, the fluid just flows out of the valve thru the power beyond port.

Then next thing this stream of fluid encounters still flowing on its way back to the tank is the first of several remote valves. Again if the valves are not operated, the fluid flows on to the 3 point valve and then it dumps into the tank. The pump is constantly sucking fluid from the tank thru the suction filter and passing it out the "pressure" port to start this fluid journey all over again. I don't know the fluid flow specifications for your tractor, but you can look them up, but it will be many gallons per minute of fluid flow. BUT as long as no valves divert this fluid flow, there will be no appreciable pressure in the system. This is called an open center system. Fluid is flowing all the time thru all the valves in series but no appreciable pressure is developed.

This residual pressure will Usually be less than 100 lbs. And only because there is some resistance from all the hoses, valves and fittings. NOW, how does the cylinders do any work if this pressure in the system is at less than 100 lbs?

Here is how: As soon as you divert the fluid flow from this "normal" path from pump back to the tank then pressure builds rapidly in that circuit. Lets say you did operate that remote valve and divert flow into the bore of a cylinder extending the piston. The pressure builds rapidly in the cylinder and the piston starts to move, pushing any load the piston is attached to. This pressure can build to the point if the load does not move or the piston reaches the end of its stroke the pressure will build to the point that the relief valve on the pump will open. If for any reason this relief valve does not open, then the pump will explode or the engine will die trying to turn the pump or something will "give".

This is catastrophic failure. Of course normally the relief valve opens. But this is still a restriction in the oil flow and the relief valve is not meant to have the complete flow rate of the pump flowing over the relief valve for long periods of time as the oil will heat up. If you are a uneducated person you would continue to hold this remote valve open and allow the flow to continue in this manner and allow fluid to flow over the relief valve.

You would notice a "funny sound" and the engine will likely lug down just a little, as the oil continues to heat. This is why they caution about holding a valve open after the piston of a cylinder has reached the end of its stroke. As you have sense enough to let it go and it will snap back to neutral and allow the flow to continue on its original journey back to the tank. OF COURSE if it is a detented valve, then it WILL NOT snap back to neutral will it?

THIS IS WHY DETENTED VALVES ARE DANGEROUS FOR UNEDUCATED PERSONS. You might actually send fluid to a cylinder with a detented valve and when it reaches the end of its stroke just let it sit there with the relief valve screaming and the oil heating up. Or if you hold it back with a bungee cord it can do the same thing. OR if you send fluid to a remote that has nothing plugged into it, it will do the same thing. The fluid flow is looking into a "brick wall" in this case, there is no where for the fluid to go so the relief valve opens as long as that valve is held open either by a detent or a bungee cord or just by your uneducated hand.

Of course this is NOT the same thing as using a bungee cord to send fluid to the backhoe valves because the backhoe valves are going to send the fluid on to the tank. Preferably by dumping it into the fill port of the tank for the least amount of restriction. Remember fluid just flows on its merry way, many gallons per minute until it meets a restriction, then pressure develops when the fluid meets a restriction.

I hope this "book" helped some.