Im working on 2 scenarios:

1

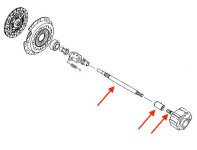

replace the main shaft, splined coupler and PS pump shaft, but hard to find this parts. I asked hoyetractor, not shure if they ship to The Netherlands.

2

I got a clutch disc, main shaft, splined coupler, PS pump from an 1510, almost identical but sadly different splines.

The idea I have is to have a custom shaft for the PS pump which has 186D splines on the output and 1510 splines on de input side.

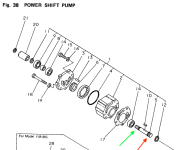

Green arrows = 1510 parts

Red arrow = custom, 1510 splines

Blue arrow = custom, 186D splines

Or a splined coupler after the PS pump which has 186D splines on the output and 1510 splines on de input side, not shure if that is possible to produce...

What do you guys think?

Any ideas how to open the PS pump? I removed the 2 bolts and the circlip on the output side, but it doesn't open much further than a couple of mm.

Are some steps missing, or does it need more force?