bmaverick

Super Member

- Joined

- Sep 17, 2013

- Messages

- 6,877

- Location

- Beloit-WI

- Tractor

- Yanmar YM2610 ■YANMAR GURU■ EXTRAORDINAIRE

The tractor is repainted and I have no idea which parts are original or maybe put together form other tractors.

On the inside of the dashboard there's still the lime green color.

Here are some pic's:

Just enough rebuild for a test drive earlier:

View attachment 680445

This one is last summer:

View attachment 680446

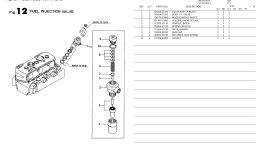

I do have the parts manual which is available on internet.

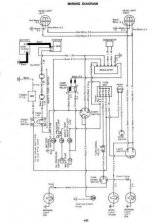

In the meantime also got a service manual, but it is incomplete.

Doesn't cover the electrical parts and some other sections.

Your Yanmar is not an early green. It's painted JD green. So, with that said, you actually own a YanDeere YD186D :laughing: