briancreed

New member

- Joined

- Jun 19, 2008

- Messages

- 13

This is my first post, but I have been lurking around here for a while... You guys definitely know whats going on. I don't know if it's customary for a first time poster to seek advice, but I guess I'll give'r a whirl.

I recently bought 80 acres that needs completely refenced. I've been around farms all my life, so I know a thing or two about fencing, but I am by no means an expert. I'd like to build a fence that will last a lifetime, with the usual repairs and upkeep of course.

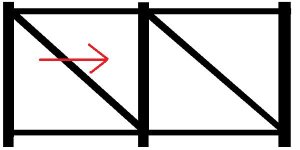

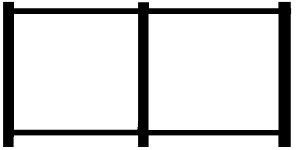

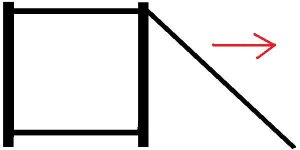

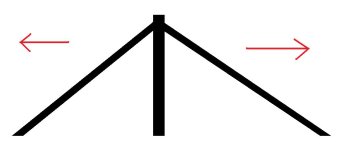

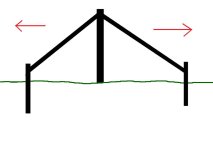

My plan is to use 4" pipe for the corners, braced with 8' long 2 7/8" pipe top and bottom and a diagonal. I am going to try to attach a sketch to show what I'm talking about. I plan on using these double h-braces at all corners, and every 330' or 660', not sure which (advice?). I am going to run 47" Red Brand Field Fence (9 guage top and bottom wires) around the whole property, with a hot wire across the top through t-post caps, and one in the middle.

I plan on using 6' t-posts spaced every 12', with 52" sticking above the earth.

I will be containing cows, horses, and possibly sheep and goats. Also, I'd like to keep it semi-dog proof (another plus for the field fence).

Is the design on these h-braces adequate? Do I need the cross bar? What size of pipe should I use (sch 30, sch 40, etc) I plan on sinking the posts 6' in the ground (skid steer with auger rental), and concreting them in. I also considered filling the pulling post to the top with concrete before it is capped.

What would be a fair price to pay a welder to notch and weld these pipes on for me?

How often should I run another h-brace to hold up the fence? Obviously for all corners, grade changes, etc, but how often on a straight stretch?

And last but not least, how should I attach the field fence to the corner posts? I've never put it up before, so I have no idea. I was thinking of stretching it tight like barb wire and then wrapping the ends around the post, but not sure how to go about this.

Any help would be greatly appreciated. I'm sure I'll have more questions in the future, so I apologize in advance for my lack of knowledge.

I recently bought 80 acres that needs completely refenced. I've been around farms all my life, so I know a thing or two about fencing, but I am by no means an expert. I'd like to build a fence that will last a lifetime, with the usual repairs and upkeep of course.

My plan is to use 4" pipe for the corners, braced with 8' long 2 7/8" pipe top and bottom and a diagonal. I am going to try to attach a sketch to show what I'm talking about. I plan on using these double h-braces at all corners, and every 330' or 660', not sure which (advice?). I am going to run 47" Red Brand Field Fence (9 guage top and bottom wires) around the whole property, with a hot wire across the top through t-post caps, and one in the middle.

I plan on using 6' t-posts spaced every 12', with 52" sticking above the earth.

I will be containing cows, horses, and possibly sheep and goats. Also, I'd like to keep it semi-dog proof (another plus for the field fence).

Is the design on these h-braces adequate? Do I need the cross bar? What size of pipe should I use (sch 30, sch 40, etc) I plan on sinking the posts 6' in the ground (skid steer with auger rental), and concreting them in. I also considered filling the pulling post to the top with concrete before it is capped.

What would be a fair price to pay a welder to notch and weld these pipes on for me?

How often should I run another h-brace to hold up the fence? Obviously for all corners, grade changes, etc, but how often on a straight stretch?

And last but not least, how should I attach the field fence to the corner posts? I've never put it up before, so I have no idea. I was thinking of stretching it tight like barb wire and then wrapping the ends around the post, but not sure how to go about this.

Any help would be greatly appreciated. I'm sure I'll have more questions in the future, so I apologize in advance for my lack of knowledge.