QRTRHRS

Elite Member

The few times that I used a deadman, I just placed a piece of concrete or a large rock in a hold dug into the ground to negate sinking. The tension is towards the ground. Securing to the post depends on the material which in your case is welded pipe?

I use a five foot fence for my mares and geldings. I set an eight foot post three feet into the ground with concrete. For my stallions, I go with a six foot fence and add a foot to the depth of the brace posts, ie; I use a ten foot post.

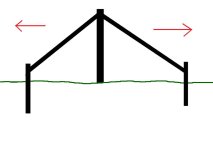

I do not like diagonal wire bracing for my braces either but I do use it. Usually, I had used tensile which is dangerous to horses especially in loop form. When I built some fence last summer, I used "Hotcote" (coated tensile wire). It was extra work but when I built my braces, I used tensile wire for the diagonals. Later, after all of my runs were in place, I took my scrap pieces of Hotcote and replace the tensile. For the single "H" braces, I used a single wire with crimps securing the bottom and a "Gripple" securing the top. Hotcote wire secures to wooden posts with a screwed on plastic clip or a stapled on piece of plastic tubing. I took the four inch pieces of tubing and slid them over the crimps and excess wire that is required with Gripples.

Reluctantly, I used a loop for my double H braces for the required equal tension. Rather than Gripples which did not secure as well in this instance, I used the ratchet style connectiors. (The coated wire is visable and the horses respect it as though it were hot)

For what it's worth, soild type can go a long way when fencing. I have used pounded PT posts sans concrete for bracing with minimal movement.

I use a five foot fence for my mares and geldings. I set an eight foot post three feet into the ground with concrete. For my stallions, I go with a six foot fence and add a foot to the depth of the brace posts, ie; I use a ten foot post.

I do not like diagonal wire bracing for my braces either but I do use it. Usually, I had used tensile which is dangerous to horses especially in loop form. When I built some fence last summer, I used "Hotcote" (coated tensile wire). It was extra work but when I built my braces, I used tensile wire for the diagonals. Later, after all of my runs were in place, I took my scrap pieces of Hotcote and replace the tensile. For the single "H" braces, I used a single wire with crimps securing the bottom and a "Gripple" securing the top. Hotcote wire secures to wooden posts with a screwed on plastic clip or a stapled on piece of plastic tubing. I took the four inch pieces of tubing and slid them over the crimps and excess wire that is required with Gripples.

Reluctantly, I used a loop for my double H braces for the required equal tension. Rather than Gripples which did not secure as well in this instance, I used the ratchet style connectiors. (The coated wire is visable and the horses respect it as though it were hot)

For what it's worth, soild type can go a long way when fencing. I have used pounded PT posts sans concrete for bracing with minimal movement.