You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Solar Panel Power Project

- Thread starter eepete

- Start date

- Views: 25195

/ My Solar Panel Power Project

#51

eepete

Platinum Member

Started this house in Dec 2005, finished in Oct 2007. I did the AC wiring, that was in Oct 2006. I put in a lot of can lights with the air tight trim kit. Then put CFLs in them. Only the 13 watt (60 watt equivalent) work. The larger sizes overheat and the case turns brown. Can lights have all the heat up high with the electronics. While there are differences in brands, it's basically a problem. LED lighting will have the same problem. As long as the light comes out the bottom and the electronics are in the top, the can light is a problem. I just had bad timing on the can lights, if I were doing it again every room would have a few sconces in them.

I did put in a number of sconces for bathroom mirror lights and also in locations where they would be on a lot such as halls and up high in the TV room. The bulbs are either "upright" (bulb up, electronics down) or horizontal. There, CFLs work great. So there is a big gap right now in fixture design and bulbs with electronics. I did have to change out the 12 bulbs in the kitchen from 23W CFLs to 60W Halogens. The kitchen/great room is where the window budget was blown, so we don't use them in the summer but do for dinner in the winter.

The key will be lights with electronics that let you remove the trim kit for a 5" can and put some thing in there. You might need to put a hole in the can to get a vent for cooling. I've seen a LED product for can lights like this, and at some point I'll check it out.

Home is set up for per-room HVAC control, as automation progresses that will happen. House has foam insulation (Selection 500), conditioned attic spaces, metal roof, 12 percent fenestration ratio, four foot overhangs and square sides with good compass orientation.

I've got two 40 amp 1000 to 1 CTs on the solar panels. I suspect that only one is needed since the currents _should_ be the same, that's all part of the learning curve. That's the first picture.

I've got 200 amp CTs on each leg of my breaker boxes, I'll have to make more of these PCBs to get that going so I can measure the power use in the house.

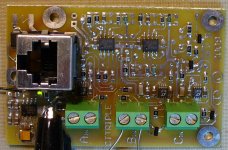

Tonight I just finished firing up a new cut of a PCB that does true RMS to DC conversion for the CTs. That's the second picture. 1 volt RMS in yields 4 volts DC out, true RMS, crest factor of about 3, frequency response good to over 1 KHz. Core part is a Linear Technology LTC1966. The PCB has 3 converters on it, they come out on a CAT5 which also has input power of 6-18 volts DC. With 12 volts for power, the board draws 5 mA including the LED.

All the wires have been run from the solar array to the house, all CAT5, connectors on. Tomorrow I should finally be able to take some readings .

.

This is right up there with trying out a new implement for your tractor....:laughing:

Pete

I did put in a number of sconces for bathroom mirror lights and also in locations where they would be on a lot such as halls and up high in the TV room. The bulbs are either "upright" (bulb up, electronics down) or horizontal. There, CFLs work great. So there is a big gap right now in fixture design and bulbs with electronics. I did have to change out the 12 bulbs in the kitchen from 23W CFLs to 60W Halogens. The kitchen/great room is where the window budget was blown, so we don't use them in the summer but do for dinner in the winter.

The key will be lights with electronics that let you remove the trim kit for a 5" can and put some thing in there. You might need to put a hole in the can to get a vent for cooling. I've seen a LED product for can lights like this, and at some point I'll check it out.

Home is set up for per-room HVAC control, as automation progresses that will happen. House has foam insulation (Selection 500), conditioned attic spaces, metal roof, 12 percent fenestration ratio, four foot overhangs and square sides with good compass orientation.

I've got two 40 amp 1000 to 1 CTs on the solar panels. I suspect that only one is needed since the currents _should_ be the same, that's all part of the learning curve. That's the first picture.

I've got 200 amp CTs on each leg of my breaker boxes, I'll have to make more of these PCBs to get that going so I can measure the power use in the house.

Tonight I just finished firing up a new cut of a PCB that does true RMS to DC conversion for the CTs. That's the second picture. 1 volt RMS in yields 4 volts DC out, true RMS, crest factor of about 3, frequency response good to over 1 KHz. Core part is a Linear Technology LTC1966. The PCB has 3 converters on it, they come out on a CAT5 which also has input power of 6-18 volts DC. With 12 volts for power, the board draws 5 mA including the LED.

All the wires have been run from the solar array to the house, all CAT5, connectors on. Tomorrow I should finally be able to take some readings

This is right up there with trying out a new implement for your tractor....:laughing:

Pete

Attachments

Last edited:

Redneck in training

Elite Member

Costs:

Cells, rails, hardware: 31,700

10 KW inverter: 5900

Wire, conduit, panels: 565

Shed: 1000 (need to go through invoices and get that nailed down better, lots of Lowes trips....

Concrete & labor: 450 (I hired a local group to help with labor- a good idea)

Total: $ 39,615

After Fed and State tax credits, it should be about $20K. I'm not including my labor.

I have a contract to buy $1669 worth of power each year, which in the narrowest sense of "payback" means 12 years. The system has a 20 year life, where that means it outputs 90% of it's original capacity.

Most discussions of payback have subtle biases built in. I'll bet very few tractor owners can come up with a payback time for their equipment. So payback times tend to be things people manipulate to justify what they wanted in the first place. Seems unlikely I'm that objective and an exception to the rule.

Things that modify the payback time are:

Future cost of electricity and if a time of use billing goes into effect.

Cost of lost opportunity of money (think "If I had left that money in a money market or bond fund, would I be better off in 20 years?")

Is your labor really free? Cost of lost opportunity for my time.

So if power cost don't increase, and interest rates or bond rates go back up into the 5-7 percent range, I should have kept my money. If this area went to a 30 cents per KWH time of day use (like some parts of California) and the interest rates and bond rates stay below 2.5%, I look like a genius with a 6 year payback and making about $2700 per year or so.

If you look at this from a strictly economic point of view, you can't justify it. But by the same stringent rules, I couldn't justify my tractors (vs. hiring the big jobs out). At this point in the solar game, people playing have justifications beyond the simple economics.

As for the tracking system and panel angle, this fixed array is certainly the simplest thing to do in terms of moving cost and semi-anual maintenance. It is probably representative of what you would see in a residential environment. Which leads me to part of the why:

I was ready to launch a home automation product in 2009 that is best for new residential construction in the 3000 to 6000 sq foot home size. Yeah, I can call them all right :laughing:. But there are lots of people spending $10K to $100K on solar panels. With no new software or sensors, I can monitor all that stuff so they can look at their energy use and generation from the house or office. And then after that there's a "Oh yeah, it also does home automation too" moment. So this will let me learn all about this sort of thing and help me start up a new business.

In my county in NC alone there are 46 small PV installations, and over 330 in the state. Another part of "why" is because it is an interesting project and I enjoyed doing it. Being an early adopter is usually tricky and expensive. I know people who paid $5K in 1985 (or about $15K in todays dollars) to by a IBM PC with a _full_ 620K (or so) so they could type letters and write programs. I spent $2K in 1983 for an 8 Mbyte hard drive for my home computer I built. I spent $2.5K in 1971 for a used PDP-8 computer. All that paid of handsomely as time marched on. If I had waited for computers to become economically viable, the catch up game on the technology would have been too much.

I mentioned at the start of this post about biases, I want mine to be clear and fully admit that on economics alone, solar PV is not there.

I'm going to do about 3 posts next with a thought on solar PV power. A heads up to the monitors of the site, if it's too off topic or deemed political nuke it and there will be no hard feelings. I think there are some interesting aspects to solar PV down the road that are worth thinking about. Lets NOT have a thread about global warming, energy tax subsides, and the like. Those have been beaten to death already. I'm just trying to explain what I did, give some of my thoughts as to why I did it, and then get people to think about what (if any) role solar PV might have for the U.S.

Pete

What justification? People by Porsches when Yaris would do. I rest my case.

saltman

Silver Member

Yes I will admit SD County has weather that will permit low power use and still enable you to be in comfort but I am about 70 miles east of the ocean so it does get warm in the summer and cool in the winter. Nothing like NC or Texas but we do have four seasons at 3,300 feet that far from the Ocean.

I had the house built with a 30 foot roof, used metal reflective roofing and R-30 in the attic, 2x6 walls with r-19. The house stays cool once it's cooled and I suspect ( just finished in May) that it will stay warm as well once warmed.

Our climate allows me to open all the windows at night, which get's it down to 70 or so at night and then I close it up during the day and maintain the 20 degree difference during the day. M

I had the house built with a 30 foot roof, used metal reflective roofing and R-30 in the attic, 2x6 walls with r-19. The house stays cool once it's cooled and I suspect ( just finished in May) that it will stay warm as well once warmed.

Our climate allows me to open all the windows at night, which get's it down to 70 or so at night and then I close it up during the day and maintain the 20 degree difference during the day. M

saltman

Silver Member

Sorry, I got carried away and then posted before I was done. What I was trying to say is yes my climate is ideal for low power use and solar but most climates could use solar if they built the home efficiently and conserved.

In California people have no clue and try to run hot tubs, ac units, and track lighting with Solar, then think they are saving the planet because they are only using 1200kwh a month!

In California people have no clue and try to run hot tubs, ac units, and track lighting with Solar, then think they are saving the planet because they are only using 1200kwh a month!

Sorry, I got carried away and then posted before I was done. What I was trying to say is yes my climate is ideal for low power use and solar but most climates could use solar if they built the home efficiently and conserved.

In California people have no clue and try to run hot tubs, ac units, and track lighting with Solar, then think they are saving the planet because they are only using 1200kwh a month!

I saw this clip with the actor Larry Hagman bragging about how his yearly bill is only 12 bucks or something. His solar system costs 750 grand with about half of it covered by incentives. What?? Someone shake this guy to see if he's breathing!

Rob

eepete

Platinum Member

Update:

I have a months worth of solar panel data. We've made 1.8 MegaWatt hours of power, worth about $200 :dance1:. The panels provides about 47% of the power the house needs, with that percentage getting larger as we head into cooler weather. At that 47% level, our electric bill is more than cut in half (get more $ for power we make than $ we pay on a per KWH basis).

Still waiting for a net-zero day...

Pete

I have a months worth of solar panel data. We've made 1.8 MegaWatt hours of power, worth about $200 :dance1:. The panels provides about 47% of the power the house needs, with that percentage getting larger as we head into cooler weather. At that 47% level, our electric bill is more than cut in half (get more $ for power we make than $ we pay on a per KWH basis).

Still waiting for a net-zero day...

Pete

sodamo

Super Star Member

- Joined

- May 20, 2004

- Messages

- 15,879

- Location

- Big Island, HI

- Tractor

- LS XR4140H (Mine) BX2380 (wife’s)

Awesome!!!!!!!

Loren49

Platinum Member

I just found this thread - interesting projects - we each have an opinion on what is a conservative setup vs what is extravagant. I've had a standalone system since 1982 in northern NY. (about 50 miles south of Canada) Used to rely more on wind but for the past 15 years mostly solar. I have 10 panels @ 85 watts and store in lead acid batteries. (1200 amp-hr) I have found that having the panels in a vertical position over the winter months is much more useful. With the amount of snow we get (and freezing rain/sleet) it simplifies life. The noon sun is low enough in the sky that there is little decrease in output. My home is a distance from the grid so I went standalone.

Loren

Loren

I just found this thread - interesting projects - we each have an opinion on what is a conservative setup vs what is extravagant. I've had a standalone system since 1982 in northern NY. (about 50 miles south of Canada) Used to rely more on wind but for the past 15 years mostly solar. I have 10 panels @ 85 watts and store in lead acid batteries. (1200 amp-hr) I have found that having the panels in a vertical position over the winter months is much more useful. With the amount of snow we get (and freezing rain/sleet) it simplifies life. The noon sun is low enough in the sky that there is little decrease in output. My home is a distance from the grid so I went standalone.

Loren

Loren, I'm south of you at about the 42 lat here and I set my panels on homemade supports. The angle I used is around 23 degrees, pretty verticle. I set them for optimum winter power. These panels put out about 1400 watts but more panels to come along with a couple of windmills in the front field and a small hydro.

Pete, impressive!

Rob