Planning to drain and put in new hydraulic/transmission fluid in the near future. Any words of wisdom? Particular fluid to use? I致e read about there being the possibility of multiple drain plugs to be sure to drain, is this the case on a YM165?

Thanks.

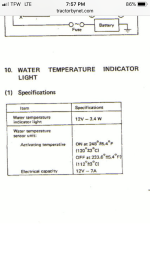

OK. But first on the running temperature. You are right, warning comes on 248 & goes off at 233 deg. F. But just because it can run hot doesn't mean it should. Probably the most valuable thing that such an extended high temp. range really gives us is a sound argument for pumping water around a cooling loop rather than counting on the magic of thermosiphon circulation.

But what we're stuck with here is a thermosiphon system. So we make it as good as we can. And it would be nice if we could induce the cooling system to get down around 215 to 225 F. Things like gaskets work better at that temp, and even engine oil is in a more range where it was designed to work best.

So double check that your 70/30 water antifreeze mix is mostly water and less antifreeze, right? Not vice-versa. Reason is that anti-freeze has a poor coefficient of heat transfer.

And then make sure that fan is working to pull the air through the radiator fins rather than around the outside or in from the sides. Tractors don't have vehicle velocity to help force air through the radiator, they do it all with the fan.

We force the air path to go the right way in two simple ways: First is to make sure air is not being pulled uselessly through the gap between the copper radiator and the steel radiator mount. If there is a gap, get some dry foam rope window caulking - nothing sticky or in a can....we're using the flexible polyurethane rope used to seal around windows and doors. At Home Depot four bucks buys a lifetime supply. Or maybe you've got some laying around. It's the kind of material a tractor guy is likely to have in the attic or barn, no? You can force it into the gap with the flat end of a carpenter's pencil.

Now back in message #66 look at the picture and thatside screen part 20. Does your tractor have that screen? I sure hope so, those side screens are shaped that way on purpose. They help direct airflow a lot. The thermosiphon needs them for the side resistance, rather than for the screen. You can try covering part of the screen with masking tape and see it that helps the fan pull more air through the radiator. Any change should be obvious on the temperature gauge in a few minutes.

The transmission filter is a cleanable one made of stainless screen. You'll want to have a couple of new gaskets before starting: namely the three screw mounting gasket (get several) and the inside grommet. I'm assuming you have access to a YM165D parts book. If not, put that on the wish list.

You didn't mention the engine air cleaner but it's worth a chat. That engine air filter is a really crazy construction. It is worth every penny of the replacement price just to marvel at. I won't spoil your surprise. But as you snap that air filter with it's little swirl fins into it's custom cushioned air box you will begin to develop a feel for why Yanmars lasted so long....,why they cost so much more than the competition, and a real admiration for the kind of design engineer who could sell his bean-counting bosses on why they needed such a piece of art on their lowest end rice paddy tractor.

Back to the hyd/tranny. It's a good one. Only flaw is that it shares its lube oil with a hydraulic pump. And of course that's only a minor flaw based around the fact that mechanical gearboxes and hydraulic pumps have completely different ideas about what constitutes their preferred lube fluids. So I'd use JD303 Hy-Gard. Go get the original good juice straight from the JD dealer. BTW, 303 Hy-Gard was also the recommendation by Yanmar for your machine back when it was first built. Hy-Gard is a lube that is oriented to please the hydraulic system and still do a decent job in the gear box. Get the standard viscosity Hy-Gard, not the new Low Viscosity Hy-Gard. The tranny holds 2.5 gallons.

The Front Axle is next. It drains from the ends as well as the middle....., and depending on how good the draining went, it can take up to 3/4 of a gallon of John Deere GL-5 Gear Oil SAE 80W-90 to refill. Some people use other fluids instead in the front axle; JD 303 Hy-Gard is one of those other fluids. You could do that. I've never heard of it being a problem. And I've done it myself. And yes, I've even seen plain old motor oil used without problems. So you pick one.

But that front axle is all about low speed sliding friction components with lots of high dollar $$ precision machined parts (it just had to have been that same crazy Yanmar design engineer) type of elliptical & bevel type gears with strong wiping action and we do know those kinda gears really benefit from GL-5. Yanmar used to recommend 90 SAE Gear Oil but that was because the 80W-90 type hadn't been invented for Gear Oils back then. You want the 80W-90. You are down at JD anyway to get the Hy-Gard, so get a gallon of their 80W-90 GL-5 basic Gear Oil. You don't need the 80W-90LS (limited slip) or the new 75W-90 synthetic. Good old GL-5 80W-90 Gear Oil will do. But maybe do include a little funnel with a rather long tube down to the filler hole. More on that below.

Perfectly refilling that front axle can involve hours of waiting for for the oil to make it down the funnel and out from the center axle housing to the ends of the axle housing where it has to migrate through the maze of bearings to where the bevel gears live. And even as all this is supposedly happening, there's no way to tell for sure if it really happening - or has happened - or where the oil actually went. So whenever you quit, be sure to check it in a few days. Or continue filling until the level seems to be somewhere between half way up the drive axle inside the center section ..... to a max of all the way at the top of that inside rotating drive axle. Not the housing, we are trying to measure down through that hole to the horizontal axle you can almost see down if you could look inside the fill hole on the top of the axle. It you could do that, the top of the rotating inside axle ought to be about 2" below the hole where you are putting oil in.

To get this filling procedure done just right, it really helps if you have a selection of small sticks to poke around with in the fill hole, a flashlight, and eyes that are conveniently mounted on individual stalks like a crawdad.....

Enjoy !

rScotty