You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Senior design project - a "Swamp Thing" tracked vehicle clone

- Thread starter Garauld

- Start date

- Views: 245827

More options

Who Replied?

/ My Senior design project - a "Swamp Thing" tracked vehicle clone

#131

The Fred

Veteran Member

You'll need to design the tank with a low spot for the fuel pickup, all fuel injected gas tanks have an internal sump to "capture" the liquid in one area around the fuel pickup. If you catch even one slug of air the engine will stall immediately and you'll have to fool around restarting the thing.

I've been there a few times over the years and learned the hard way. Your tank design looks long and flat on the bottom; hopefully you can design in a few baffles and a low area to mount your internal sump for the fuel pump pickup to sit. Some sumps have one way doors to let liquid in and not be able to reverse out.

Your attention to detail is very nice. Don't forget safety, like the battery being very close to the gas tank which could short out on your metal gas tank in a bad situation. Do your seats have side air bags in them? Might be time to remove them.

Here's one I did for an old Monte Carlo with a big block, 30 gallons and if you look closely you can see the sump I scrounged out of a Toyota Corolla gas tank and mounted it in the bottom. I hammered out a 3/8" low area to mount the sump. It still works very well to this day.

Regards, Fred

I've been there a few times over the years and learned the hard way. Your tank design looks long and flat on the bottom; hopefully you can design in a few baffles and a low area to mount your internal sump for the fuel pump pickup to sit. Some sumps have one way doors to let liquid in and not be able to reverse out.

Your attention to detail is very nice. Don't forget safety, like the battery being very close to the gas tank which could short out on your metal gas tank in a bad situation. Do your seats have side air bags in them? Might be time to remove them.

Here's one I did for an old Monte Carlo with a big block, 30 gallons and if you look closely you can see the sump I scrounged out of a Toyota Corolla gas tank and mounted it in the bottom. I hammered out a 3/8" low area to mount the sump. It still works very well to this day.

Regards, Fred

balsam

Member

Hi Garauld: I really like your work, very well organized. Great job on the track drive sprockets.

Take a look at the specs. on this Argo. AURORA 950 SX. I always compare my designs to something similar, as a comparison, just as a check on my calculations.

This Argo used the same 40hp Kohler engine I have in mind and I suspect the weight would be similar, or likely a lot higher as it sits 4 and because of the weight of the drive mechanism to drive all 8 wheels. Of course this is only a rough comparison.

I can figure out what the hp. per lb. drive ratio would be with a hydrostatic transmission(pressure gage and flow rate) but of course that would be after the fact. I’m not sure how you would compare the ease of driving a wheeled vehicle as compared to a tracked one. I would think they would be somewhat similar.

Just found out I need cataract surgery so that may set back my start date.��

Looking forward to more pictures.

Take a look at the specs. on this Argo. AURORA 950 SX. I always compare my designs to something similar, as a comparison, just as a check on my calculations.

This Argo used the same 40hp Kohler engine I have in mind and I suspect the weight would be similar, or likely a lot higher as it sits 4 and because of the weight of the drive mechanism to drive all 8 wheels. Of course this is only a rough comparison.

I can figure out what the hp. per lb. drive ratio would be with a hydrostatic transmission(pressure gage and flow rate) but of course that would be after the fact. I’m not sure how you would compare the ease of driving a wheeled vehicle as compared to a tracked one. I would think they would be somewhat similar.

Just found out I need cataract surgery so that may set back my start date.��

Looking forward to more pictures.

Garauld

Gold Member

Thanks for the reminder about the sump and baffles in the fuel tank. I will ensure they are in there. I plan to put the battery in a plastic case so that should make it safer sitting next to the gas tank.

Garauld

Gold Member

plumbstraight

Silver Member

- Joined

- Dec 16, 2010

- Messages

- 236

- Location

- Washington state and Ak

- Tractor

- 5300 John deere,53 harry ferguson, ck20 kioti, 135 ferguson, 350jd dozer, k40 kubota excavator

-> this design uses a front wheel drive car with an open differential , i.e, it does not have posi-traction. I will use one of the axles as the power side of the driveshaft to the other (also open) differential at the front of the chassis. One of the engine axles will either a) need to be anchored to the frame so the power will be transmitted to the driveshaft or b? the gears inside the differential need to be welded thus "locking" the diff.

-> the front driven differential has a brake rotor placed on each side - these are used for steering. Pull the right steering lever and the right brake caliper actuates thus transferring power to the left track to turn right. Make sense?

Be better to weld up the spider gears. If you fix the other axle to the frame to stop it from turning it will double the speed of the axle driving the system.

Garauld

Gold Member

I welded up the spider gears in the engine transmission diff. for longevity reasons. One of the previous replies discusses this. The front diff powering the two sprockets needs to stay open for steer braking purposes.

Garould, interesting thread and project. I like your choice of engine and drivetrain. I see discussion of a governor and or restictor plate. I would suggest simply adjusting the throttle cable to limit your power if need be. I built a small tractor with a similar drive train. Was hung up on a governor but found out a foot throttle was all that was needed. Governors are great for some applications such as grinding feed. Just screwing around, no need. As for your welded spiders in the tranaxle that will work well. I am on my second tractor utilizing welded spiders and a transaxle turned ninty degrees as yours is. Zero problems. One issue will be when you brake to turn the free side is going to turn faster like a car with one wheel on ice. Not a deal breaker but will make for some fast turns. Like your in-board brake setup.

Garauld

Gold Member

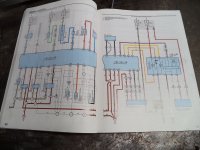

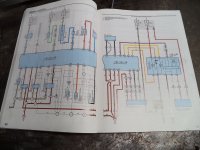

This past week I spent some hours going thru the factory wiring manual (which is actually, very useful) trying to identify what parts of the harness will not be need for Snowzer. I plan to re-purpose a number of the fuses for the new lighting and other accessories. I guess about 70% of this mess could be removed:

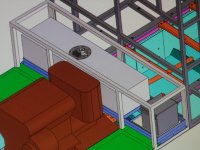

I also welded up the lower part of the cargo frame and made up the subframe that supports the 12.5 gal. fuel tank and battery:

I plan to fab a gas tank shortly which will then allow me to try and start it sometime soon. Once I know it runs, I'll get back to finishing up the axles, driveshaft and cab frame.

I also welded up the lower part of the cargo frame and made up the subframe that supports the 12.5 gal. fuel tank and battery:

I plan to fab a gas tank shortly which will then allow me to try and start it sometime soon. Once I know it runs, I'll get back to finishing up the axles, driveshaft and cab frame.

strantor

Platinum Member

This past week I spent some hours going thru the factory wiring manual (which is actually, very useful) trying to identify what parts of the harness will not be need for Snowzer. I plan to re-purpose a number of the fuses for the new lighting and other accessories. I guess about 70% of this mess could be removed:

View attachment 586082 View attachment 586083

I also welded up the lower part of the cargo frame and made up the subframe that supports the 12.5 gal. fuel tank and battery:

View attachment 586084 View attachment 586085

I plan to fab a gas tank shortly which will then allow me to try and start it sometime soon. Once I know it runs, I'll get back to finishing up the axles, driveshaft and cab frame.

This is very exciting progress. Your work looks very professional, much attention to detail. This thread is inspiring me to make progress on my own projects.