W8BYA

Silver Member

It's great that you posted this also and all the work you're doing to solve it. Wow! This "There is over 1.6 V(p-p) RFI riding on top of the 13.8 VDC power line !"

is amazing and explains so many problems people (may) experience using LEDs.

Before retiring I was a troubleshooter, primarily consumer electronics.

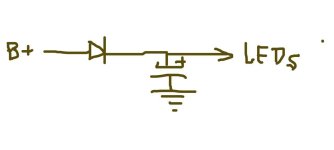

The diode/cap idea was a simple isolation thought which would drop LED supply by about 0.65-0.7V (with it's smps wouldn't affect light output).

It would be more complexity but a separate battery such as an inexpensive (like Everstart 230 cca $22), LEDs powered by it, that battery then charged by isolation diode from tractor alternator.

Me...I'd be thinking of ditching LEDs in favor of halogen!

I'm a little intrigued by the diode/cap idea, would you be willing to e-mail me a sample schematic drawn on the back of a napkin of a simplified example of it's execution? My e-mail is w8bya at mchsi dot com. I would like to see that and possibly mess around with it purely because I'm a geek and miss doing engineering work so it would be fun some cold wintery night.

Also, I can understand wanting to ditch LED's all together but we need to remember that not everyone has issues with them because as noted earlier it takes two to tango.....you need a trouble maker but you also must have something susceptible to that trouble maker. If your equipment already has filtering or simply is not susceptible then heck keep using them. They are very bright and draw way less power. And they will outlast the tractor and any halogen bulbs <g>.

)...very simple. B+ is power source, cathode has electrolytic cap to ground, this is now source to lights.

)...very simple. B+ is power source, cathode has electrolytic cap to ground, this is now source to lights.