MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 58,347

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

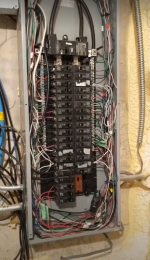

As far as I know 2 circuits, one marked "garage" in the panel in the basement, which services the garage door and all the outlets. The defunct shed circuit is the other one, I traced that to it's breaker with a circuit tracer tool thingie.

But the conduit carrying those wires out from the panel is jammed full of other wires too, there's no room to stick two more 10 ga wires in there. So, would need to run a new conduit.

The reason I ask is because here ( I don't know about "there" ), you can only run 1 circuit from the main house to any outbuilding. If you want to run more than 1 circuit, you have to install a sub-panel.

Our house, when we bought it, had a cobbled up mess of wires going to a small garage and the larger garage. He combined 2 110v circuits to make 220 in the garage, junk like that. I pulled it all out and ran proper cable for a 220v sub-panel.

We only have 100 amp service in the house.

I installed a 50amp 2-pole breaker in the house and used that to feed the new sub-panel in the garage.

In the garage sub-panel, there is a 30amp 2-pole breaker, a couple 20amp GFCI single pole breakers for the pool and the small garage, a lighting circuit, and a couple outlet circuits. I never weld when the pool is running. Other than that, I can weld with the Hobart 110v mig, or the 220v stick welder while the air compressor is running.

What I'm getting at, is it might be better for you to really evaluate all the things in the conduit going to your garage, see how many wires you could eliminate, and if that would free up enough space to pull in heavier wires for a sub-panel.

Good luck with your project. :thumbsup: