Seven Gables

Platinum Member

- Joined

- Jan 30, 2019

- Messages

- 607

- Location

- Northern lower Michigan

- Tractor

- jd 5115m , Ford 545D, Kubota M8540, NH t4.105 , Ford 5030, Ford 4830, NH TN 95FA, Volvo EC60E

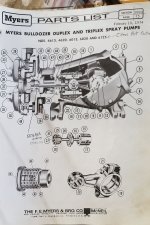

Actually if my old foggy noodle is remembering correctly that special tool was a pipe with two ears and had two uses . You set the leathers into top of cylinders then placed the cup shaped nut on top , then placed the pipe in the bowl of the nut and whacked pipe with small sledgehammer. This drove both pieces down into cylinder . Once leather was in cylinder remove nut and drive leather over threaded rod onto brass backing plate, the pipe allowed threaded rod to fit inside it as you hammered.

Then once leather was seated to backing plate and threaded rod was thru the leather you’d put nut on and tighten.

Been a long time but that’s best I remember

Then once leather was seated to backing plate and threaded rod was thru the leather you’d put nut on and tighten.

Been a long time but that’s best I remember