You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

16' opening Door header: on load bearing wall

- Thread starter LD1

- Start date

- Views: 61858

/ 16' opening Door header: on load bearing wall

#51

s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,548

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

A pair of 14's would allow a deflection of .583. Just outside the mark for l/360. But certainly doable. But it don't save me much. They are only $7 less than 16". So still would be $176 per beam.

Since you seem to be a fan of the LVL, how are they gonna be in 30 years being in an unconditioned building?

And I may well be crazy, but I still think I can build a stronger beam out of conventional lumber, and do it for less money.

I'll wager those LVL beams will be more stable in 30 years under variable humidity conditions than any standard lumber you can buy nowadays! You'd have to go back in time about 50 years to get decent stable lumber, and then it still won't match the strength capability of LVL (about 2900 psi fiber bending stress versus about 1200 for SYP or DF) or the ability to be stable in multiple axes.

Another option is plate steel sandwiched between 2x12, or heck it may even work with 2x10 or 2x8, would need to do the math. But I don't see how it can be done with just 2x lumber unless you have the option of going wide and stacking as many as needed to get the rating.

I am not seeing that much deflection with the LVLs in my cookbook tables, but would want to hand calculate the numbers to say for sure. But keep in mind that L/360 is generally for plaster/drywall finishes with cracking potential. Most other framing is calculated for L/240 and then checked to be sure material is within specs for the calculated bending and shear stress.

s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,548

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

Yet another idea. Seems it would be as just about as strong as the earlier beam I drew, and a tad cheaper too. But don't rely on a single thin sheet of plywood to hold it together.

View attachment 394850

Increase that to about a zillion pieces with high strength glue and no fasteners (like a glue-lam), and then you will begin to approach the strength of homogenous top to bottom material. You can certainly do the math on that combination you drew, but you need to use individual 1/12 * b * h^3 for the components and transfer the loads together appropriately. It will not calculate as a single piece. If beams could be made this simplistically, we wouldn't have glue-lams and LVLs!

LD1

Epic Contributor

I just used an online beam deflection calculator. Most are setup for steel. But just change the appropriate modulus of elasticity to 1.9 million for the lvls, input the load and span and i4 and those are the numbers it gave me.

Again, even the latest combo beam of 2x10's with a 2x8 and 2x4's in the middle, its still probably overkill cause I will likely add knee braces 2'x2' on each side, reducing the total span a good bit, then the metal siding on the outside....I think it would make a quite stiff beam with 6000# load applied.

But I am glad I am getting this hashed out now so I have a game plan come spring.

Again, even the latest combo beam of 2x10's with a 2x8 and 2x4's in the middle, its still probably overkill cause I will likely add knee braces 2'x2' on each side, reducing the total span a good bit, then the metal siding on the outside....I think it would make a quite stiff beam with 6000# load applied.

But I am glad I am getting this hashed out now so I have a game plan come spring.

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,789

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

i am not a fan of laminated stuff. it is the glue. it acts more like a filler. to much glue = bad, not enough = bad. the nearest thing i can think of would be, cpu's in your computers, and putting a heat sink fan on the cpu. the compound ya use fills in micro areas, so there a better direct heat sinking between cpu, and the cooler. if ya put to much it gushes out, and that micro film more thickness = not able to overclock the cpu that much further. not enough, and the CPU overheats and fry's itself. for lumber, and glue, perhaps peanut butter sandwich, might be something, or a honey sandwich. (toasted even) might be closer to things.

the glue yes may hold stuff together, and fill in gaps, so the lumber is less likely to slip, but it does not really form crystals, like concrete will (older concrete is the harder it becomes). the sheering / twisting s219 getting at. yes glue helps, but transferring like end posts on a fence. is not really there, were there is a X or a / or \ at an end post to keep the end post aligned and keep it from being pulled out.

==============

a roll up door = seals the best, if you were to heat/cool the barn/shed, they require a bit more higher tolerances of things being square level, without battling the tracts and adjusting them.

slider doors = they are less forgiving of things out of square / level. but at same time, they do not seal as good as a roll up door.

if you went with roll up door/s i dont see how knee braces, would work without interfering with tracts of the roll up doors.

your big door on shed/barns, is were a lot of air moves, which also brings a lot of moisture, and sudden heat/cooling as the air moves around the cracks at the door. this is going to cause extra stress to the lumber around the door. causing some lumber to expand/contract more than other areas. along with causing glue to contract/expand at different rates. this puts extra stress "long term" not to mention moisture / mildew possibly to the area.

with above i am not a big fan of laminated stuff, more so plywood at the big door/s, when speaking long term. it could mean the difference part of the year a door fitting rather snug (hard to open), to loose (almost coming off the tracts). it may only be 1/2" but that is still a good amount.

==============

your posts for the barn, are not going to be square and perfectly level with each other, just not going to happen, there will be twsits, bends, warping going on, just how lumber is. a good carpetener knows how hide the non squareness / un eveness, almost to long or to short, and make it look good and hopefully work long term.

i still say there going to be some "side deflection" rafters, or manufactured / engineered trusses. it is the post opposite of the door/s that will also move to some amount. along with the truss pivoting. that will allow some movement at the header/beam going across the door. the 2x4's that go across the top of the trusses, so you can nail down your metal roofing. really does not give the truss that will go in or at near center of your beam much structural support.

other words the beam is going to naturally want to bend down and outwards due to load on it. and i think your still trying to avoid some of the side loading that will go on at the beam.

the glue yes may hold stuff together, and fill in gaps, so the lumber is less likely to slip, but it does not really form crystals, like concrete will (older concrete is the harder it becomes). the sheering / twisting s219 getting at. yes glue helps, but transferring like end posts on a fence. is not really there, were there is a X or a / or \ at an end post to keep the end post aligned and keep it from being pulled out.

==============

a roll up door = seals the best, if you were to heat/cool the barn/shed, they require a bit more higher tolerances of things being square level, without battling the tracts and adjusting them.

slider doors = they are less forgiving of things out of square / level. but at same time, they do not seal as good as a roll up door.

if you went with roll up door/s i dont see how knee braces, would work without interfering with tracts of the roll up doors.

your big door on shed/barns, is were a lot of air moves, which also brings a lot of moisture, and sudden heat/cooling as the air moves around the cracks at the door. this is going to cause extra stress to the lumber around the door. causing some lumber to expand/contract more than other areas. along with causing glue to contract/expand at different rates. this puts extra stress "long term" not to mention moisture / mildew possibly to the area.

with above i am not a big fan of laminated stuff, more so plywood at the big door/s, when speaking long term. it could mean the difference part of the year a door fitting rather snug (hard to open), to loose (almost coming off the tracts). it may only be 1/2" but that is still a good amount.

==============

your posts for the barn, are not going to be square and perfectly level with each other, just not going to happen, there will be twsits, bends, warping going on, just how lumber is. a good carpetener knows how hide the non squareness / un eveness, almost to long or to short, and make it look good and hopefully work long term.

i still say there going to be some "side deflection" rafters, or manufactured / engineered trusses. it is the post opposite of the door/s that will also move to some amount. along with the truss pivoting. that will allow some movement at the header/beam going across the door. the 2x4's that go across the top of the trusses, so you can nail down your metal roofing. really does not give the truss that will go in or at near center of your beam much structural support.

other words the beam is going to naturally want to bend down and outwards due to load on it. and i think your still trying to avoid some of the side loading that will go on at the beam.

If the OP is using a more or less standard roll-up door, then the knee braces won't be in the way of track, because the track mounts on the inside of the posts and the door just faces the posts. A lot of roll up doors have the knee braces in the corners (although they are not really knee braces) so that the corners have angles and the door doesn't look so blocky. Similarly, it shouldn't matter to the door if the header deflects a little, because the door won't be attached to the header.

I also don't think that the header is going to have a lot of lateral force on it (at least not more than any other place in the building), because while the top chord of the truss is trying to push it down and out, the bottom chord of the truss will serve as a tie from one side of the building to the other, thus canceling the lateral force.

I like the OP's latest design for the header. Again, I think it is more than adequate, because the loadings that we are using are most likely worst case scenarios that won't come to pass, and even if they do, then I doubt that the header would be the sole failure point in the building.

I think that plenty of good ideas have been kicked around and the OP is free to do as he and his budget will allow, and for that, I am thankful.

Good luck and take care.

To the OP: You did clearly state your criteria and loadings in your earlier posts; I don't know how I missed them, but I found them when I re-read the thread. There was no need for assumptions on my part.

I also don't think that the header is going to have a lot of lateral force on it (at least not more than any other place in the building), because while the top chord of the truss is trying to push it down and out, the bottom chord of the truss will serve as a tie from one side of the building to the other, thus canceling the lateral force.

I like the OP's latest design for the header. Again, I think it is more than adequate, because the loadings that we are using are most likely worst case scenarios that won't come to pass, and even if they do, then I doubt that the header would be the sole failure point in the building.

I think that plenty of good ideas have been kicked around and the OP is free to do as he and his budget will allow, and for that, I am thankful.

Good luck and take care.

To the OP: You did clearly state your criteria and loadings in your earlier posts; I don't know how I missed them, but I found them when I re-read the thread. There was no need for assumptions on my part.

radioman

Super Member

I know what you are trying to say -- but its really not 4k pressure in the middle. a well engineered truss SPREADS the weight. The reason why i wrote the last post is to make a point. Your weight is split and the direct down pressure is right on the ends.

Picture this my way for a min.. In the middle of the barn, you have trusses overhead. You want a garage door parallel to the ends. I am NOT worried about the snow loads. the trusses already takes care of the weight to spreaded to the ends. so no need to overthink the header beam. Now -- if you built a wall that is same direction as your ridge line yeah you need to worry about the strength of header as its sharing the load if you have the header touching the trusses.

Picture this my way for a min.. In the middle of the barn, you have trusses overhead. You want a garage door parallel to the ends. I am NOT worried about the snow loads. the trusses already takes care of the weight to spreaded to the ends. so no need to overthink the header beam. Now -- if you built a wall that is same direction as your ridge line yeah you need to worry about the strength of header as its sharing the load if you have the header touching the trusses.

LD1

Epic Contributor

I know what you are trying to say -- but its really not 4k pressure in the middle. a well engineered truss SPREADS the weight. The reason why i wrote the last post is to make a point. Your weight is split and the direct down pressure is right on the ends.

Picture this my way for a min.. In the middle of the barn, you have trusses overhead. You want a garage door parallel to the ends. I am NOT worried about the snow loads. the trusses already takes care of the weight to spreaded to the ends. so no need to overthink the header beam. Now -- if you built a wall that is same direction as your ridge line yeah you need to worry about the strength of header as its sharing the load if you have the header touching the trusses.

I think you are missing the design. The door IS goign to be on a wall running the same direction as the ridge line. And being a 16' door and 8' OC trusses, That puts the END of a truss right in the middle of the header.

So the trusses, Sets on the "walls" on two sides of the building. So 1/2 of the entire truss load is carried on each end of the truss.

On all the rest of the trusses, these are resting right on top of posts. But one truss will only rest on a header board, no post under it.

Go back and look at the picture in post #3. That "Wall" you are looking at with the door opening is NOT an end wall, it is the wall running parallel to the ridge (eave wall).

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,789

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

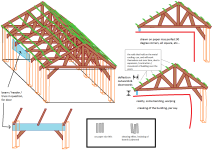

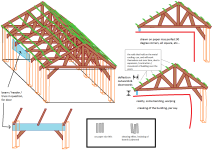

still raining, bordem....

scratch and sniff of making above diagram in paint.

View attachment making of stick building in paint.png

scratch and sniff of making above diagram in paint.

View attachment making of stick building in paint.png

LD1

Epic Contributor

Not bad for just using paint.

That is exactally the truss/header in question. Nice way of illustrating it. I think some still don't understand how I am coming up with point loading to the tune of 6000#, or don't understand the difference between eave and gable wall. That illustrates it better than I could have.

And I still believe that a made up stacked beam in the 20" ish depth and 3 layers wide should be overkill and would never fail.

I have seen longer spans with lesser material that never failed over 40 years. Yes there was sag, but no failure.

That is exactally the truss/header in question. Nice way of illustrating it. I think some still don't understand how I am coming up with point loading to the tune of 6000#, or don't understand the difference between eave and gable wall. That illustrates it better than I could have.

And I still believe that a made up stacked beam in the 20" ish depth and 3 layers wide should be overkill and would never fail.

I have seen longer spans with lesser material that never failed over 40 years. Yes there was sag, but no failure.