Santa Craig Cringle

Silver Member

- Joined

- Mar 3, 2014

- Messages

- 205

- Location

- Lawrence County, AL

- Tractor

- Current - 2021 Kioti CX2510, Previous - 1959 Ford 881

Saturday I went out to my newly acquired 34 completely raw undeveloped acres and attempted to do some brush hogging. I currently own a relatively newer Kioti CX2510HST 25 hp tractor/loader/backhoe. I have not used it for anything up until this point for doing anything other than some light gardening work at my current house. I realize my tractor is under sized for that type of acreage but it's what I have to work with at the moment.

I bought a 5 foot rotary cutter used last weekend, with a stump jumper. I also realize that 5 foot may be slightly oversized for my tractor, but I opted to go to the 5-foot over the 4-foot and take smaller bites.

For my first attempt, I attempted to clear some area in the woods and quickly discovered that rotary cutters are not meant for uneven terrain. Besides just the shear difficulty of maneuvering with it, I experienced a lot of issues with binding my top link. Only after I got home and watched some more brush hog videos, did I discover going on uneven terrain was kind of a no-no, especially going in and out of valleys/dips/etc.

Other issues I had is that my hydraulic top link quick connect kept popping loose. Not sure why that was happening.

And the other fittings on my top link kept loosening, causing me to loose hydraulic power. I'm assuming all this was because of the binding. I guess I'm pretty lucky I didn't do any major damage to the PTO but it didn't bind up. But you live and learn. Kind of a tractor rookie here. Have some seat time, but not at doing anything more than a little light gardening work for years.

Another problem I had was that the previous owner had put a rubber no flat tire on the rotary cutter wheel. The tire was not a perfect fit and kept slipping off, and I had to fight to get it back on the wheel only to have it pop off again, 3 or 4 times. By the end of the day the wheel was pretty bent up and the fork was kind of leaning within the rear bracket, so I'm going to have to replace the whole assembly, I think.

With all this fighting of the equipment, I underestimated the need for hydration as well. I was working in 90 degree temps - I have not done any significant amount of work in those temperatures in at least 5 years. By 1pm I was rationing my water. By 4pm I think I was in the early stages of heat stroke or something similar. Lesson learned, bring a lot more water than you think you need. Since the AC in my truck doesn't work, bring my 18V cordless fans and plenty of batteries too.

I ended the day brush cutting in a largely level field with about 4 foot of weed growth. Went slow, kept my loader bucket down and curled back. Found several large tree stumps that I thankfully spotted by keeping the bucket low. When the bucket would start to slide up the stump, I was going slow enough that I could back up and change course.

It was a good day, but kind of a rough first day out.

Re-thinking a lot of my preconceived ideas of how I was going to go about building a home here now that I've actually spent a few hours on the ground. We're not building for awhile, so I'm going to continue to get to know my property over the next year or two before breaking any serious ground.

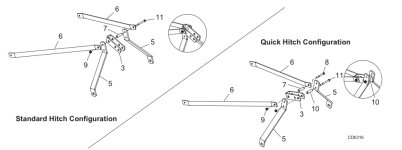

After struggling with mounting the brush hog, I think I'm going to buy a Speeco Quick E-Hitch also. And seriously looking at a PTO Link (quick connect). When it's hot, I really don't want to be struggling with those.

I bought a 5 foot rotary cutter used last weekend, with a stump jumper. I also realize that 5 foot may be slightly oversized for my tractor, but I opted to go to the 5-foot over the 4-foot and take smaller bites.

For my first attempt, I attempted to clear some area in the woods and quickly discovered that rotary cutters are not meant for uneven terrain. Besides just the shear difficulty of maneuvering with it, I experienced a lot of issues with binding my top link. Only after I got home and watched some more brush hog videos, did I discover going on uneven terrain was kind of a no-no, especially going in and out of valleys/dips/etc.

Other issues I had is that my hydraulic top link quick connect kept popping loose. Not sure why that was happening.

And the other fittings on my top link kept loosening, causing me to loose hydraulic power. I'm assuming all this was because of the binding. I guess I'm pretty lucky I didn't do any major damage to the PTO but it didn't bind up. But you live and learn. Kind of a tractor rookie here. Have some seat time, but not at doing anything more than a little light gardening work for years.

Another problem I had was that the previous owner had put a rubber no flat tire on the rotary cutter wheel. The tire was not a perfect fit and kept slipping off, and I had to fight to get it back on the wheel only to have it pop off again, 3 or 4 times. By the end of the day the wheel was pretty bent up and the fork was kind of leaning within the rear bracket, so I'm going to have to replace the whole assembly, I think.

With all this fighting of the equipment, I underestimated the need for hydration as well. I was working in 90 degree temps - I have not done any significant amount of work in those temperatures in at least 5 years. By 1pm I was rationing my water. By 4pm I think I was in the early stages of heat stroke or something similar. Lesson learned, bring a lot more water than you think you need. Since the AC in my truck doesn't work, bring my 18V cordless fans and plenty of batteries too.

I ended the day brush cutting in a largely level field with about 4 foot of weed growth. Went slow, kept my loader bucket down and curled back. Found several large tree stumps that I thankfully spotted by keeping the bucket low. When the bucket would start to slide up the stump, I was going slow enough that I could back up and change course.

It was a good day, but kind of a rough first day out.

Re-thinking a lot of my preconceived ideas of how I was going to go about building a home here now that I've actually spent a few hours on the ground. We're not building for awhile, so I'm going to continue to get to know my property over the next year or two before breaking any serious ground.

After struggling with mounting the brush hog, I think I'm going to buy a Speeco Quick E-Hitch also. And seriously looking at a PTO Link (quick connect). When it's hot, I really don't want to be struggling with those.