Probably as you described but check out the explaination (all greek to me) on pg 102 of FO-44 under Paragraph 186.

You thoughts?

Sevan,

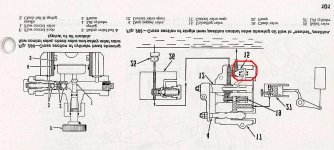

Please look at the pic below. It is difficult to cover the operation with one paragraph. If you look at the porting and get

yourself some colored pencil can determine the flow routing. It shows hyd fuel being pumped from the sump, how it travels

to main safety relief valve and at then in the hyd spool valve. There are many things happening for the fluid to travel thru

different openings and ports. You can read it very carefully and figure out and most likely you'll forget it the next day... I did

bottom line is the concept;

1) hyd system is live and always pumping when the tracrtor is on.

2) Takes finite amount of liq to fill the cylinder for any given height.

3) when the height is archived something has to be done(I.e, as you can not suck out of the bottle conversely

can not put

more in it than the volume allows).

4) when the 3 pt height is archived all the oil has to be diverted to sump.

5) if you were to lower the 3 point then some oil has to go back thru the same spool. You got a busy cross section with traffic

cops and street light to regulate the traffic and in this case

oilflow.

The reason I suggested to do this at the last option was the complexity of inside and adjustment that comes with it. Any how,

even I would do exactly the same as you are doing even if it was futile, if nothing else it is a great learning opportunity. I'd put

the stuff back and give it a go, may be you have cleared the obstruction... I hope.

By the way, I kind of asked this question several times, I know the FEL works, but look at the flow arrow and where it ties to the

bottom of the spool valve( that is the banjo connection on the inlet to the spool). Have you actually loosened it and observed

flow prior to valve spool assembly??

JC,