Why is it so hard for people to understand that for 99% of the jobs on this forum, there is no need for 7018 to be in a rod oven!

ullinghair:

I would argue that for 99% of the jobs on this forum, there is no need for 7018 rod.

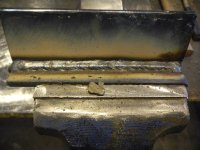

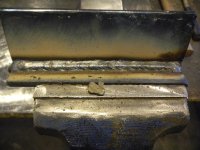

Most everything I have done at home, with the stick, certainly isnt 7018. Cause on the old craftsman AC tapped machine, 7018 dont run at all. Flat out wont do it. But that machine has ran several hundred pounds of 6013, 7014.

We arent talking 1" thick plates here. Most of the stuff people on this forum (myself included) are dealing with is 1/8" - 1/4" stock. 6013 and 7014 are more than capable of good penetration on this stuff.

This trailer is about 20 years old now, and dont have a single weld on it that ISNT 6013. And has hauled MANY MANY loads of wood.

6013 is fine if someone knows how to use it. It might not be the best, or the strongest, but is still good rod.

If you need to hang a 10 pound sign on the wall, and have the choice of using 1/4" x 3/4" fastners or 1/2" x 2" fastners, what would you do?? Sure the 1/2 x 2" fastners would penetrate more and hold more. But given that the sign will bend and tear and crumple long before the 1/4 x 3/4 fastners fail, is it really any better??

I have said my piece, and I will leave this thread alone now. I am by no means a "pro" weldor. I just get tired of hearing 7018, 7018, 7018 all of the time. yes, it is an excellent rod, and very strong. (not pertaining to this thread).....but a newbie welder that wants to weld a bracket or hook to something to hang a tool or whatnot, certainly dont need 7018. And given the difficulty of running 7018 on AC, for a newbie, look into other rods.