RangerRick

New member

- Joined

- Dec 30, 2004

- Messages

- 9

- Location

- Southington, CT

- Tractor

- JD 3520, JD 410H, JD 50D, JD 400G, Kobelco 115dz

Hi Rawinok2,

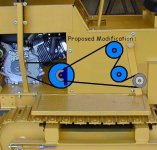

I agree with Renze on this proposed modification. As shown, your dozer will be going about twice as fast as you have it now. You may be breaking keys or belts and if they don't break, you may be thrown off the back of the machine if the engine is powerful enough.

As I stated previously, changing the pulley on the motor to half its diameter will slow the speed down by half. Did you try that yet? You can put idlers in the center of the belt (top and bottom) if you have too much belt slop.

Changing to the smaller pulley would give you twice the torque at startup also.

Seems to me that all you need to do this would be a new pulley and possibly a new belt if you don't want to introduce the idlers to take up the slack.

Rick

I agree with Renze on this proposed modification. As shown, your dozer will be going about twice as fast as you have it now. You may be breaking keys or belts and if they don't break, you may be thrown off the back of the machine if the engine is powerful enough.

As I stated previously, changing the pulley on the motor to half its diameter will slow the speed down by half. Did you try that yet? You can put idlers in the center of the belt (top and bottom) if you have too much belt slop.

Changing to the smaller pulley would give you twice the torque at startup also.

Seems to me that all you need to do this would be a new pulley and possibly a new belt if you don't want to introduce the idlers to take up the slack.

Rick