Luke'sScreenName

Elite Member

- Joined

- Mar 1, 2015

- Messages

- 3,709

- Location

- Lakes Region, NH

- Tractor

- Kubota MX4800 with BH-90X hoe; Hustler FastTrack 48; B3300SU (sold); 1969 Case 680B CK (sold)

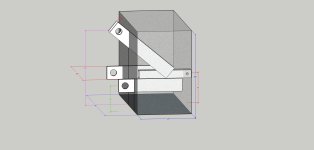

I am starting to give up trying to work out the dimensions I should use for my ballast block by looking at the dimensions of the implement side of various quick-hitches on the market. Instead, perhaps I should just use standard CAT-1 dimensions - IF I can find them - and then hope for the best if I ever get a quick-hitch.

Your thoughts?

Ken

This is what I would do in your choice of Cat 1 or Cat 2 dimensions (I picked cat1... and would be ok with 1500lbs of weight). :2cents:

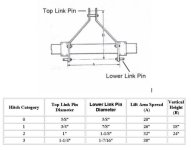

FYI: The critical dimensions are that the spread between the lift arms not be too wide and that the distance between the lift arms and the top link not be too much. Both can be a 1/2inch to even 3/4inch short (maybe more).