4shorts

Elite Member

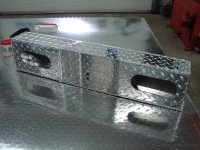

Here's a little project I'll share with you. It will take me up until the weekend to complete it but some of you might find it interesting. I won't say what it is right now but as time goes on you'll probably guess it. It is an accessory for the Ironworker and a useful one.

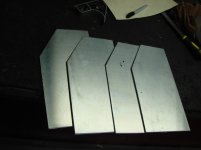

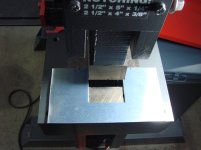

I'm using 1/8th aluminum plate for the project. I used the plasma to cut the bulk of it from the sheet and then used the Ironworker to make the fine cuts. The brake you see in one of the photo's is on of the two breaks I built last year for my forklift project. Stay tuned there's more to come

I'm using 1/8th aluminum plate for the project. I used the plasma to cut the bulk of it from the sheet and then used the Ironworker to make the fine cuts. The brake you see in one of the photo's is on of the two breaks I built last year for my forklift project. Stay tuned there's more to come