You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can you braze a hydraulic line?

- Thread starter 59 Sons

- Start date

- Views: 27466

More options

Who Replied?

/ Can you braze a hydraulic line?

#41

4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,039

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

You got your PHD in brazing. Looks good. Is it an injury risk if it fails?

It has a floor pan that bolts back over that so there’s virtually no chance of oil spray hurting anyone if it were to leak.

DJ54

Elite Member

- Joined

- Jan 20, 2009

- Messages

- 4,632

- Location

- Carroll, Ohio

- Tractor

- IH Farmall 656 gas/ IH 240 Utility/ 2, Super C Farmalls/ 2, Farmall A's/ Farmall BN/McCormick-Deering OS-6/McCormick-Deering O-4/ '36 Farmall F-12/ 480 Case hoe. '65 Ford 2000 3 cyl., 4 spd. w/3 spd Aux. Trans

Wish I'd have seen this yesterday. In the aircraft industry, they repair hydraulic lines by buffing the line, then wrap mechanics wire around the tubing, approx. 1/2" either side of a leak, then Silver Solder. I have a buddy who is an aircraft tech, and has made more than several repairs like this. I asked if that was a temporary fix, and he said no. Really surprised me they would do such a thing. He said you'd probably be surprised how many commercial aircraft are in the air with that type of repair.

Plus the fact most commercial aircraft hydraulic pressure runs 3,000 psi.

Plus the fact most commercial aircraft hydraulic pressure runs 3,000 psi.

Smokeydog

Elite Member

Wish I'd have seen this yesterday. In the aircraft industry, they repair hydraulic lines by buffing the line, then wrap mechanics wire around the tubing, approx. 1/2" either side of a leak, then Silver Solder. I have a buddy who is an aircraft tech, and has made more than several repairs like this. I asked if that was a temporary fix, and he said no. Really surprised me they would do such a thing. He said you'd probably be surprised how many commercial aircraft are in the air with that type of repair.

Plus the fact most commercial aircraft hydraulic pressure runs 3,000 psi.

Need to remember wrapping with wire trick before brazing. SS safety wire?

59 Sons

Silver Member

I'm trying to imagine the function of the wire wrap. Is it supposed to reinforce the silver? Silver makes such a good patch because of its flexibility. It can handle the expansion and contraction of the steel pipe without cracking. That's why we use a higher silver brazing rod on dissimilar metal connections. If you were brazing a copper line into a steel socket, the difference in expansion and contraction during temperature fluctuations is pretty big. The high silver filler material (45-55%) can handle that stress. When we are brazing similar metals like a copper joint, we usually only use 15% silver alloy.

59 Sons

Silver Member

I guess I can see how the wire wrap would be beneficial if there is a split in the tube.

ROUSTABOUT

Elite Member

- Joined

- Jan 30, 2008

- Messages

- 3,186

- Location

- Luther Willis Hill, AR

- Tractor

- Pettibone, Ford, Massey Ferguson, International, JD, David Bradley, home mades

Yes they will. I've been running a hydra push manure spreader with a compression fitting on it for 20 years. I replaced it last year to get everything right to sell it. We'd pack 8 yards on it cleaning out chicken houses. Maybe 300 loads each clean out.I’m guessing you meant flare fitting not compression. Compression can’t handle hydraulic pressure.

DJ54

Elite Member

- Joined

- Jan 20, 2009

- Messages

- 4,632

- Location

- Carroll, Ohio

- Tractor

- IH Farmall 656 gas/ IH 240 Utility/ 2, Super C Farmalls/ 2, Farmall A's/ Farmall BN/McCormick-Deering OS-6/McCormick-Deering O-4/ '36 Farmall F-12/ 480 Case hoe. '65 Ford 2000 3 cyl., 4 spd. w/3 spd Aux. Trans

Soft mechanics wire, so it's easy to wrap around the tubing.Need to remember wrapping with wire trick before brazing. SS safety wire?

DJ54

Elite Member

- Joined

- Jan 20, 2009

- Messages

- 4,632

- Location

- Carroll, Ohio

- Tractor

- IH Farmall 656 gas/ IH 240 Utility/ 2, Super C Farmalls/ 2, Farmall A's/ Farmall BN/McCormick-Deering OS-6/McCormick-Deering O-4/ '36 Farmall F-12/ 480 Case hoe. '65 Ford 2000 3 cyl., 4 spd. w/3 spd Aux. Trans

I'm assuming to keep any solder getting inside the tubing, and contaminating the hydraulic fluid. Just solder beyond the wire to make sure it will seal.I guess I can see how the wire wrap would be beneficial if there is a split in the tube.

Egon

Epic Contributor

Yes they will. I've been running a hydra push manure spreader with a compression fitting on it for 20 years. I replaced it last year to get everything right to sell it. We'd pack 8 yards on it cleaning out chicken houses. Maybe 300 loads each clean out.

Roustabout used the proper fitting.

Flared fittings do come in different configurations and materials for different design pressure. The local hardware store likely will not be carrying the high pressure version. There are piping situations where flared fittings are not allowed.

eg. Brake line flares are not the same as plumbing flares.

ROUSTABOUT

Elite Member

- Joined

- Jan 30, 2008

- Messages

- 3,186

- Location

- Luther Willis Hill, AR

- Tractor

- Pettibone, Ford, Massey Ferguson, International, JD, David Bradley, home mades

Compression or flared?Flared fittings do come in different configurations and materials for different design pressure. The local hardware store likely will not be carrying the high pressure version. There are piping situations where flared fittings are not allowed.

ptsg

Super Member

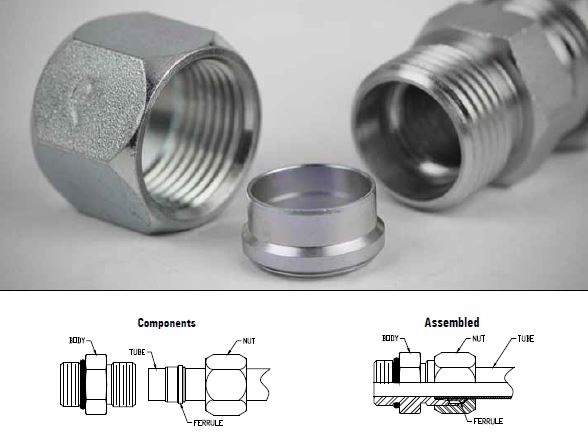

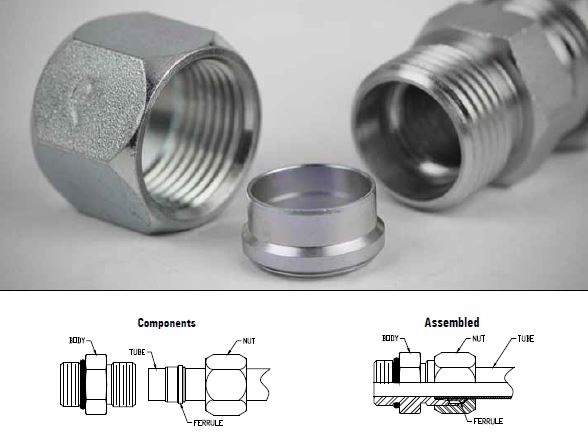

An hydraulic compression fitting doesn't necessarily have to be flared.

These things work perfectly and can/will handle some crazy pressures. A good alternative for the OP in case he needs to work on that line again. Just cut a section of the pipe off and replace with a short piece of hose with compression fittings.

These things work perfectly and can/will handle some crazy pressures. A good alternative for the OP in case he needs to work on that line again. Just cut a section of the pipe off and replace with a short piece of hose with compression fittings.

ROUSTABOUT

Elite Member

- Joined

- Jan 30, 2008

- Messages

- 3,186

- Location

- Luther Willis Hill, AR

- Tractor

- Pettibone, Ford, Massey Ferguson, International, JD, David Bradley, home mades

I've also had a compression fitting on my 1967 F250 since 1990. Right off the back of the power steering pump. It's an ACE hardware fitting. I'm not recommending it, but they do work. On my own things I tend to use any kind of cobbled together crap that will work.Roustabout used the proper fitting.

Flared fittings do come in different configurations and materials for different design pressure. The local hardware store likely will not be carrying the high pressure version. There are piping situations where flared fittings are not allowed.

eg. Brake line flares are not the same as plumbing flares.

ROUSTABOUT

Elite Member

- Joined

- Jan 30, 2008

- Messages

- 3,186

- Location

- Luther Willis Hill, AR

- Tractor

- Pettibone, Ford, Massey Ferguson, International, JD, David Bradley, home mades

Advice. I wouldn't weld it up while it is on the tractor. No way to make sure nothing is left inside from welding. Just take it apart until you get the line off. Go to a hydraulic place and get a new line made. We just had several hard lines made for a John Deere 540 B-G log skidder. They all fit just fine. Of course we took the old ones for them to pattern off of. Personally I would arc weld the lines. I've done it several times on larger equipment, usually changing the line later when things slowed down. On heavy equipment lines usually rub together more than split and fail. I put rubber hoses or insulate lines from each other while I'm in there.I have a split steel hydraulic line on my Kubota M59. I ordered and have the replacement line. After two days disassembling my tractor, I have realized it is impossible to remove and replace the line. It was apperantly installed early in the construction of the tractor and never intended to be replaced. Which would have been fine if the materials had been higher quality. It was not damaged, it failed. So now I'm thinking I will have to cut the old one out and have a flexible line built on to the Kubota ends. That got me thinking they might have to braze hose fittings onto my cut tubes. So can I braze over the material defect in my tube?? I braze copper lines regularly and brass and steel fittings occasionally. I usually use a 45-55* silver braze with flux on steel or dissimilar metals. Sometimes I will cap with a 15* silver just to beef it up. Any reason I can't do this on a steel hydraulic line??

Just take your machine on down until you can get the line off and go to a good hydraulic shop and let them have it. In the end, it is the best way to get this accomplished. Ive seen all types of predicaments and circumstances.

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Lost track of how many times I've done this. Should have read to the end before posting.Advice. I wouldn't weld it up while it is on the tractor. No way to make sure nothing is left inside from welding. Just take it apart until you get the line off. Go to a hydraulic place and get a new line made. We just had several hard lines made for a John Deere 540 B-G log skidder. They all fit just fine. Of course we took the old ones for them to pattern off of. Personally I would arc weld the lines. I've done it several times on larger equipment, usually changing the line later when things slowed down. On heavy equipment lines usually rub together more than split and fail. I put rubber hoses or insulate lines from each other while I'm in there.

Just take your machine on down until you can get the line off and go to a good hydraulic shop and let them have it. In the end, it is the best way to get this accomplished. Ive seen all types of predicaments and circumstances.

ROUSTABOUT

Elite Member

- Joined

- Jan 30, 2008

- Messages

- 3,186

- Location

- Luther Willis Hill, AR

- Tractor

- Pettibone, Ford, Massey Ferguson, International, JD, David Bradley, home mades

I imagine we all do.

IndyJay

Super Star Member

- Joined

- Apr 23, 2021

- Messages

- 18,449

- Location

- S.E. Indiana

- Tractor

- 2021 Kioti DK4510MS w/Loader, Grapple Prev: Massey 1250

Before there was duct tape, there were steel coat hangers. The original multi-purpose DIY that was always close at hand.One of the metal hydraulic lines for my dozer split. My neighbor happened to stop by while I was taking it off and he said that he could weld it with a coat hanger. He used a gas acetylene torch and the metal coat hanger, and it's held perfectly for over a decade now.

My wife has replaced all of the house coat hangers with plastic, But I kept a dozen or so in the garage because sometimes that is all you need is a little piece of coat hanger to do a task where nothing else seems to work.

Egon

Epic Contributor

A coil #9 wire has many uses! Its more feline than coat hangers.

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Yep. Additionally wads of baling wire stashed in the barns, sheds, gate posts, behind the pickup seat, anywhere there might be a need.A coil #9 wire has many uses! Its more feline than coat hangers.

59 Sons

Silver Member

An old friend of mine used to lock her keys in the car so often that she started keeping an extra coat hanger safely locked in her trunk.

Here are some similar links:

- Replies

- 19

- Views

- 3K