Mrphoenix80

New member

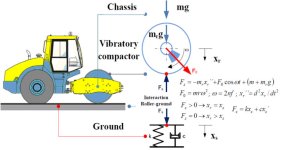

SO I needed a lawn roller. I went and picked one up today. After about 3 or 4 seconds of deep thought. I was thinking about making it vibratory. Quick search and I found some 12v motors with 200lbs of force.

The builder stated the roller is 1100lbs empty and almost 2300lbs filled with water. I was thinking if I added 2 of these above the axle that could give the vibration I want. This will help to compact gravel and milling for my driveway as well as smoothing ruts in the lawn.

What are your thoughts? Has anyone here done this?

The builder stated the roller is 1100lbs empty and almost 2300lbs filled with water. I was thinking if I added 2 of these above the axle that could give the vibration I want. This will help to compact gravel and milling for my driveway as well as smoothing ruts in the lawn.

What are your thoughts? Has anyone here done this?