My dump bed drops down when it is about a foot and a half from all the way down. Dalton hydraulic cylinder and pump, 2200 lb trailer weight (guess,) tandem axles at 3500 lbs each, 5'x12' box. The guy I got it from thinks it may be air in the line but he ordered a one-way flow control valve which he says could fix it. How do I fix this? Also, he is making a pair of ramps so I can tow a small skid steer in it. He recommends that they be five feet long to make to be easy to manage and that they will work if I tilt the bed up (lowering the back end,) and then drop the bed down when I get to the top. Is this crazy? Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

dump bed drops down

- Thread starter 1claydude

- Start date

- Views: 15719

More options

Who Replied?

/ dump bed drops down

#1

AKKAMAAN

Veteran Member

Is the dumping design your own? (cylinder and "scissor leverage" etc) or/and can you refer to a online/upload picture of the dump design, and plumbing?My dump bed drops down when it is about a foot and a half from all the way down. Dalton hydraulic cylinder and pump, 2200 lb trailer weight (guess,) tandem axles at 3500 lbs each, 5'x12' box. The guy I got it from thinks it may be air in the line but he ordered a one-way flow control valve which he says could fix it. How do I fix this? Also, he is making a pair of ramps so I can tow a small skid steer in it. He recommends that they be five feet long to make to be easy to manage and that they will work if I tilt the bed up (lowering the back end,) and then drop the bed down when I get to the top. Is this crazy? Thanks.

Air?? hmmm....

Design related?? Maybe, especially if dumping (up) starts with cylinder horisontal, and ends with cylinder vertical....

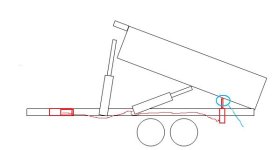

Hi, not my design. It starts out about 4" (should have measured) below horizontal at the lower mounting point and gets up to a 50 or 60 degree angle. I bought the trailer on craigs list from a guy who said he built it and had a manufactuers and dealers licence which he just decided not to renew earlier that week. I believe it was designed for a sissor lift and he changed his mind, but not the design, to keep the price down. Here are some photos. Let me know if you need more.

AKKAMAAN

Veteran Member

Hi, not my design. It starts out about 4" (should have measured) below horizontal at the lower mounting point and gets up to a 50 or 60 degree angle. I bought the trailer on craigs list from a guy who said he built it and had a manufactuers and dealers licence which he just decided not to renew earlier that week. I believe it was designed for a sissor lift and he changed his mind, but not the design, to keep the price down. Here are some photos. Let me know if you need more.

ooops...can't see any pic's yet...

EDIT:I do think you problem is from the design....My idea is this...

If cylinder starts around horizontal, it has a disadvantaged leverage position to the bed. I can see that it takes very high pressure to make bed start raising. The more the cylinder extends the better leverage, and lower pressure. When lowering the bed, at the position when it has "about a foot and a half from all the way down", the cylinder is almost fully retracted.

Would be great to see a video clip, showing the cylinder motion during a full dump cycle, up and down.

Leejohn

Elite Member

AKKAMAAN hit the nail right on the head....

AKKAMAAN

Veteran Member

AKKAMAAN hit the nail right on the head....

Thanks LeeJohn!:thumbsup:

This is a very poor design, and it is basically impossible to use a cylinder like this, with out a linkage system to make leverage equal over the entire dump cycle. So it is not a hydraulic problem. It is a mechanical design problem. This current design do need extreme pressure to initiate the dump cycle, and over the time bed raises, leverage gets better and takes the stress of the cylinder and the rest of the design.

If you look at the horisontal position of the cylinder, it will rather push the bed backwards than lift it....:laughing:

The main limiting issue is that we need a cylinder that have a long stroke, but are very short retracted (to fit under the bed, and still allow ground clearance)

The are ways to make this work with out linkage, but then we have to use either 2 or more cylinders, or better using a multiple segment, telescopic cylinder, with a trunnion mount. (95% of all dump trucks overseas, use trunnion mount telescopic cylinders, centered under the bed. That also allows dump side ways too. Notice how the cylinder is in a almost square angle to the bed during the entire dump cycle )

A telescopic cylinder have some unique features for a design of a bed dump. It utilize the largest "piston diameter" at the start of the cycle, and the more the bed raises, the weigh on the cylinder decreases, and the smaller diameter segments can keep extending, at a faster speed.

Is it fixable? Do you have a picture of one done correctly? How far out of horizontal does it have to be? What about a shorter ram of similar strength and drop down the lower end (being careful not to bottom out?)

AKKAMAAN

Veteran Member

Is it fixable? Do you have a picture of one done correctly? How far out of horizontal does it have to be? What about a shorter ram of similar strength and drop down the lower end (being careful not to bottom out?)

If you keep current cylinder, and mount a second similar cylinder, reduced diameter very possible, in the nose of the trailer. That will help to control both forces and the lowering speed. This second cylinder can not med pinned into the trailer. When the current cylinder "takes over" this front cylinder will disconnect from the trailer.

This 2nd cylinder shall be connected with a "T" to the line to the current cylinder.

This will of course slow down the start of the cycle.

With this arrangement, you can also replace the current cylinder with a smaller diameter cylinder.

A one way flow control needle valve is still a good idea to control/maintain a SAFE lowering speed.

Thanks so much! This is a real help! I am sold. Now I need to work out some details. I'll have to measure to see what size ram extension I need (with some overlap.) I am guessing that a 2 foot throw will be more than enough. Any recommendation on who's hydraulics to buy? I could use some help on the lower mount and should I have a pocket of some sort at the top? It seems uncomfortable to assume that the ram will be in the right spot for the return trip if I don't guide it in some way. Maybe a combination skid plate and angle iron. Do you still need a video? All thoughts greatly appreciated !

AKKAMAAN

Veteran Member

Thanks so much! This is a real help! I am sold. Now I need to work out some details. I'll have to measure to see what size ram extension I need (with some overlap.) I am guessing that a 2 foot throw will be more than enough. Any recommendation on who's hydraulics to buy? I could use some help on the lower mount and should I have a pocket of some sort at the top? It seems uncomfortable to assume that the ram will be in the right spot for the return trip if I don't guide it in some way. Maybe a combination skid plate and angle iron. Do you still need a video? All thoughts greatly appreciated !

hahaha...I am happy to sell this idea to you!!

Cost?? A video when you are done with your rebuild!!!

Good luck!

ps. No video needed now, since you are already "sold"...LOL

wdchyd

Elite Member

Akkamaan,

I've seen short nubby cylinders added to Ladder Fire Trucks using this same arrangement.....adding 2 single acting cyls ( or d/a using bottom port only) added at the frame with short stroke and larger bore dia will do basically the same as you describe without the larger cyl in the way........the base end securely mounted near the rear pivot pins and the rod end not connected to the frame (used for just the initial lift)......

You could use maybe a 3 or 4 " bore with a 4 or 5 " stoke.......it would new a flow control as you said to control the down speed and tee them to the main cyl...........

The results would be the same...........

I've seen short nubby cylinders added to Ladder Fire Trucks using this same arrangement.....adding 2 single acting cyls ( or d/a using bottom port only) added at the frame with short stroke and larger bore dia will do basically the same as you describe without the larger cyl in the way........the base end securely mounted near the rear pivot pins and the rod end not connected to the frame (used for just the initial lift)......

You could use maybe a 3 or 4 " bore with a 4 or 5 " stoke.......it would new a flow control as you said to control the down speed and tee them to the main cyl...........

The results would be the same...........

Attachments

How much PSI in each of the two scenarios? 5x12 bed, two 3500# axles, max load 5000#. Also, I picked up a "basket" of Moss Rock yesterday that weighed 3009 lbs (with skid and wire cage.) I saw no difference in the lifting action (like there was no weight at all) and no difference in the sudden drop if I held the remote on the way down. How come the really flat triangle formed by the two points on the cylinder and the hinge of the bed has no visible effect through the range of motion going up and is the exact opposite going down? Would it be a different story if I put 5000 lbs on it?

wdchyd

Elite Member

Probably with a heavier load it would struggle to lift the load with that geometry......the added cyls for the beginning of stroke (both senarios) would add to the lifting strength while starting and help to slow down the velocity of the oil on the last bit of stroke going down ( the flow control valve can be tuned to your liking)

If you were to put a hyd guage on the pressure line while lifting a load, you'd see that it will take alot more pressure when it starts lifting and gradually the pressure will fall back the higher it goes....with the same load on it....

The extra "Kicker cyl(s)" would probably be MORE needed for the down but will be an added benefit in the lift cycle.....

If you were to put a hyd guage on the pressure line while lifting a load, you'd see that it will take alot more pressure when it starts lifting and gradually the pressure will fall back the higher it goes....with the same load on it....

The extra "Kicker cyl(s)" would probably be MORE needed for the down but will be an added benefit in the lift cycle.....

AKKAMAAN

Veteran Member

How much PSI in each of the two scenarios? 5x12 bed, two 3500# axles, max load 5000#. Also, I picked up a "basket" of Moss Rock yesterday that weighed 3009 lbs (with skid and wire cage.) I saw no difference in the lifting action (like there was no weight at all) and no difference in the sudden drop if I held the remote on the way down. How come the really flat triangle formed by the two points on the cylinder and the hinge of the bed has no visible effect through the range of motion going up and is the exact opposite going down? Would it be a different story if I put 5000 lbs on it?

The "secrets" about dumping a bed like this are many.

1. Where is center of gravity of the bed and load combined?

2. Where is the cylinder affix point to the bed?

3. Where is the cylinder affix point to the trailer frame?

4. Where is the hinge point between bed and trailer frame?

These things will determine the size of the load (Force), the cylinder have to overcome.

5. The bore diameter (piston area) will then determine the required pressure to lift bed.

6. While bed is pivoting during the dump cycle, the effective cylinder force will change. The way your current design is, cylinder is least effective when bed is all the way down., and most effective when cylinder is fully extended (square to the bed). That means the highest pressure is required at the start of the dump cycle.

This drawing illustrates the complexity of forces and distances on a design like this. What ever your actual numbers are, everything can be calculated.

The most interesting during the dump cycle, happens within the yellow shaded area. I leave it open for discussion.