You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FEL Snow PLow size?

- Thread starter dstig1

- Start date

- Views: 21972

More options

Who Replied?

/ FEL Snow PLow size?

#21

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

Yeah it didn't take too long. There will be plenty of pics, but I'm not really going to start in on this project until the summer. No real time right now. About all I am going to do is take it apart and maybe get it over tot he sandblaster to clean it up and see what other problems are there that I can't see yet... But I might wait on that for a few weeks so it doesn't just rust over again...

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

I got some time to tear it apart today. Overall not too bad. A few bent pieces including a piece of the sector you can see in the pic below (the tab on the left is bent, compared with the one on the right and a weld is broken). A couple other small bends/dents to fix. Nothing that can't be fixed. Probably the worst finding was that the moldboard under the cutting edge was pretty rotted on one side. I may need to cut some of that out and stitch in a piece. Upper left in the photo - the black rusted areas. The pivot pins still moved, but had to be driven out of the sector. But they came out, so that's good. I will add grease fittings there.

I'm not sure if the cylinders can be re-used or not. The exposed chrome has a few pits in it, and it may tear up the seals. Dunno - that's an area I don't have much experience in. I haven't tried to move them yet. Ran out of time to mess with them.

New hardware needed all around too, of course. Gave the impact wrench a bit of a workout...

I got a rough quote of $200-300 for sandblasting which seems high to me. I may just rent a blaster and give it a try myself. Next step will probably be later this summer when I hope to get more time. I need some time to gather parts too.

I'm not sure if the cylinders can be re-used or not. The exposed chrome has a few pits in it, and it may tear up the seals. Dunno - that's an area I don't have much experience in. I haven't tried to move them yet. Ran out of time to mess with them.

New hardware needed all around too, of course. Gave the impact wrench a bit of a workout...

I got a rough quote of $200-300 for sandblasting which seems high to me. I may just rent a blaster and give it a try myself. Next step will probably be later this summer when I hope to get more time. I need some time to gather parts too.

Attachments

Looking4new

Super Star Member

- Joined

- Apr 8, 2012

- Messages

- 10,324

- Location

- Northern Ontario, Canada

- Tractor

- 2012 Kioti CK27HST w/cab

The pitted chrome on the cylinder pistons will tear up the seals. Seals are cheap, it just takes time to replace them.

LD1

Epic Contributor

I got some time to tear it apart today. Overall not too bad. A few bent pieces including a piece of the sector you can see in the pic below (the tab on the left is bent, compared with the one on the right and a weld is broken). A couple other small bends/dents to fix. Nothing that can't be fixed. Probably the worst finding was that the moldboard under the cutting edge was pretty rotted on one side. I may need to cut some of that out and stitch in a piece. Upper left in the photo - the black rusted areas. The pivot pins still moved, but had to be driven out of the sector. But they came out, so that's good. .

Doesnt look too terrible for the money.

I will add grease fittings there.

I did this to my truck plow as well.

Since I dont have a lathe, I didnt drill the pin. Instead, I drilled the plow itself as well as the sector. That way BOTH sides that the pin is in get greased. And mine didnt come out so easy. 10 minutes of pounding with a sledge

I Probably the worst finding was that the moldboard under the cutting edge was pretty rotted on one side. I may need to cut some of that out and stitch in a piece.

Yea, the meyers plows werent a great design for preventing rust. Another trouble area is usually quarter-sized holes that appear just above the cutting edge in 4 places......right where there is a back brace. Since it isnt welded solid...but the bottom 2 or so inches is, moisture gets in behind the angles and goes to town.

When I re-skinned mine, I welded it all solid to keep the moisture out from behind the back braces. And then a good paint before the accessories like the cutting edge and top flapper. And when I did pit them on, a little silicone to keep moisture from getting in behind.

I'm not sure if the cylinders can be re-used or not. The exposed chrome has a few pits in it, and it may tear up the seals. Dunno - that's an area I don't have much experience in. I haven't tried to move them yet. Ran out of time to mess with them.

Yea, it will wear out the seals and leak a little. If you are using your tractor hydraulics, I wouldnt worry about it. Because you could probabally run the plow for the tull 200 hrs til next service and it wouldnt leak enough to be a drop in the bucket. They arent under constant pressure.

But if it does get too bad, it is a PITA and about $20 each to do. Those gland nuts are on tight. If I ever do mine again, I will just buy new cylinder. baileynet.com has aftermarket replacement cylinders for like $50. For me, spending half a day and cursing like a sailor isnt worth trying to save $30 per cylinder. And since the rods are pitted, a new rod + seal kit would be even more than the whole cylinder.

New hardware needed all around too, of course. Gave the impact wrench a bit of a workout...

Stainless would probabally be a worthwhile investment here.

I got a rough quote of $200-300 for sandblasting which seems high to me. I may just rent a blaster and give it a try myself. Next step will probably be later this summer when I hope to get more time. I need some time to gather parts too.

200-300 doesnt sound bad at all if that is everything. The cost of renting a blaster + sand + a days worth of dirty and nasty work......

Go ahead and rent one if you want, but afterword I'll bet you think differently about 200-300 being high.

Good luck and keep us posted on your rebuild:thumbsup:

4shorts

Elite Member

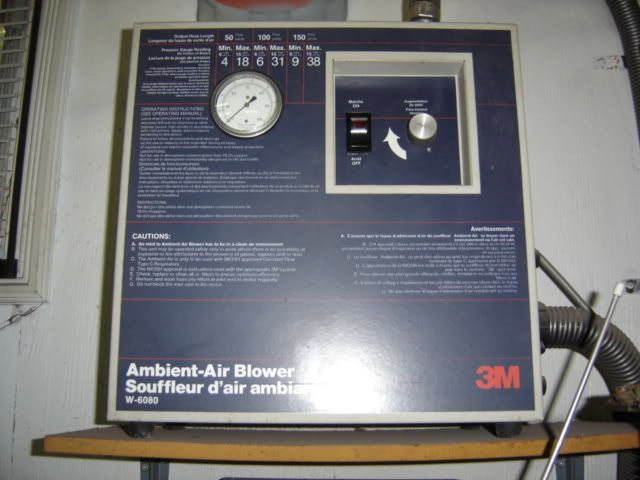

Dave it looks as if you found a really nice candidate for a tractor plow. I've done plenty of sand blasting and even made my own pressure blaster. It's one thing to rent a blaster but pease protect your lungs. I use a 3-M blower that supplies fresh air to my 3-M helmet. Yes it's expensive but how much are lungs going for these days?

If I only had one use for sand blasting I'd pay the money and get it done. It's very dangerous stuff and it's hard work my friend.

If I only had one use for sand blasting I'd pay the money and get it done. It's very dangerous stuff and it's hard work my friend.

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

Since I dont have a lathe, I didnt drill the pin. Instead, I drilled the plow itself as well as the sector.

Yea, the meyers plows werent a great design for preventing rust. Another trouble area is usually quarter-sized holes that appear just above the cutting edge in 4 places......right where there is a back brace.

When I re-skinned mine, I welded it all solid to keep the moisture out from behind the back braces. And then a good paint before the accessories like the cutting edge and top flapper. And when I did pit them on, a little silicone to keep moisture from getting in behind.

Stainless would probabally be a worthwhile investment here.

200-300 doesnt sound bad at all if that is everything. The cost of renting a blaster + sand + a days worth of dirty and nasty work......

LD1 - thanks for the tips. Wasn't sure on what you meant by drilling the pin for a grease fitting?? I was aiming to do the sector and plow like you said.

I like your ideas on preventing rust. I will apply that here. Most of the mold board seems pretty solid, so I am thinking I may patch in that one corner and call it good. I'll know better once it is blasted.

I was thinking this might need grade 8 bolts to stand up to the abuse. Do you think SS will be strong enough? It is pretty soft by comparison... This is only going to see use on my driveway, so it isn't like I am commercial plowing either...FWIW

BTW, I thought it was ironic that I ended up with a Meyers ST90, just like you said a month ago in this very thread...

Dave it looks as if you found a really nice candidate for a tractor plow. I've done plenty of sand blasting and even made my own pressure blaster. It's one thing to rent a blaster but pease protect your lungs. I use a 3-M blower that supplies fresh air to my 3-M helmet. Yes it's expensive but how much are lungs going for these days?

If I only had one use for sand blasting I'd pay the money and get it done. It's very dangerous stuff and it's hard work my friend.

Ah the old Whitecap... Yes I know it. I'll let my secret out... I work for 3M developing respirators, and have for quite a number of years. So I have access to basically any safety equipment I would ever need. I appreciate the concern, but I am well aware of sandblasting hazards (and many other hazards you have probably never heard of...), so don't worry about that. I expect it is hard, but it is also something I have never done, which makes it worth trying out. A sand blaster here rents for $25/day (plus media), so that ain't bad at all, and it's not like I'm doing an entire forklift or anything crazy like that:laughing: Oh - and thanks for your business!

I guess my thoughts on the cost of blasting were #1 I'm a cheap SOB

4shorts

Elite Member

Ah the old Whitecap... Yes I know it. I'll let my secret out... I work for 3M developing respirators, and have for quite a number of years. So I have access to basically any safety equipment I would ever need. I appreciate the concern, but I am well aware of sandblasting hazards (and many other hazards you have probably never heard of...), so don't worry about that. I expect it is hard, but it is also something I have never done, which makes it worth trying out. A sand blaster here rents for $25/day (plus media), so that ain't bad at all, and it's not like I'm doing an entire forklift or anything crazy like that:laughing: Oh - and thanks for your business!

I guess my thoughts on the cost of blasting were #1 I'm a cheap SOB, and #2, if I wanted to spend a fortune on the plow, I would have bought a nicer one in the first place (hmmm, pretty much the same as point #1...). So I'll probably give it a whirl myself and see how it goes. What is the recommendation for media? The Black Beauty stuff seems popular.

Glad to read your up on the hazards of this type of work. There are many who are not. I remember about ten years ago a friend of mine asked me to Sand blast a boat trailer for him. I told him I would and told him I'd do it just for the cost of the sand. Well he got mad with me and said he'd go a rent the equipment and do it himself which he did.

The thing that he didn't rent and couldn't rent was a good breathing apprentice but went on to do his trailer.

Before he managed to get it completed he ended up in hospital where he stayed for three weeks and he ended up loosing 40% of his lung capacity.

Now you see why I show concern about this sort of thing. I've done plenty of sand blasting and I hate it. The helmet and hoses are heavy and on days it's very hot not to mention back breaking but it's a nessassary evil to get the job done right.

I did all my collection for my musume with that 3-M gear. I purchased it new at an auction. I got the helmet, hoses and ambient pump for $250. and it was brand new at the time. I actually had to cut the boxes open to use it. I bought the full lot of them (6 lots in all) and sold the rest on fleebay and did pretty good out of it.

The black media is good stuff but clogs the blaster easily. It's more expensive (but safer) but you get less of it. It do cut good though.

The silica sand is easy to get around here but as you will know comes with many hazards but still does a great job.

Oh. I'm not a fan of stainless bolts on a plow application. They are soft, strip out easily and there are times you just can't remove them because they strip out.

Building the Brutal Blaster

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

Totally understood, Paul. Too many people don't get it when it comes to respiratory protection, and other safety equipment, and they end up injured as a result. As you note, some of those injuries can last a lifetime too.

I may give the silica sand a whirl. I need to see what I can find around here first.

You made out quite well on that system. They are pricey!

Question for you - You added a plate and a pair of rect tubes as reinforcement to the SSQA plate. What brought you to that point, and is it needed if you get a stiffer plate to start with?

I may give the silica sand a whirl. I need to see what I can find around here first.

You made out quite well on that system. They are pricey!

Question for you - You added a plate and a pair of rect tubes as reinforcement to the SSQA plate. What brought you to that point, and is it needed if you get a stiffer plate to start with?

4shorts

Elite Member

Question for you - You added a plate and a pair of rect tubes as reinforcement to the SSQA plate. What brought you to that point, and is it needed if you get a stiffer plate to start with?

The SSQA plate I used was made out of 1/4 steel. It was very strong. I did mine this way because I didn't want any surprises during the winter. I wanted to build it once and that was it. I had the extra meterial on hand so I added it plus it made it look neater in my opinion.

The only two items I changed was one, I added two skid shoes to the rear of the "A" frame. Doing that prevented the rear part of the frame from digging into the ground and the other mod was to add a trip shock to the blade to slow down the rebound of the blade after it tripped. That was a great addition to the unit.

I have a new cabbed 4240 coming in at the end of the month that belongs to a customer that's getting a similar set up as I have. Should be interesting :thumbsup:

Page with trip shock:

http://www.tractorbynet.com/forums/customization/131136-snow-plow-adapted-front-end-9.html

LD1

Epic Contributor

LD1 - thanks for the tips. Wasn't sure on what you meant by drilling the pin for a grease fitting?? I was aiming to do the sector and plow like you said.

I was talking about drilling a hole (boring) all the way through with a couple side holes for grease to get out. That way there would be just one grease fitting on the end of the pin.

I wasnt sure how you were going to do the fittings.

I like your ideas on preventing rust. I will apply that here. Most of the mold board seems pretty solid, so I am thinking I may patch in that one corner and call it good. I'll know better once it is blasted.

If you dont weld the back braces solid, at least drill a hole up through from the bottom, in the bottom angle, to let moisture out.

I was thinking this might need grade 8 bolts to stand up to the abuse. Do you think SS will be strong enough? It is pretty soft by comparison... This is only going to see use on my driveway, so it isn't like I am commercial plowing either...FWIW

I cannot make any guarantees, but I think SS would be just fine. The bolts are a pretty good size already. My ST-90 is only grade 5 hardware, and I push it with a 3500 DRW truck at a pretty good speed and havent broke anything yet. And if anything, a softer bolt would prevent you from bending/braking other things. But in reality, with a crossover valve set up right, and trip springs, it keeps parts intact pretty well.

BTW, I thought it was ironic that I ended up with a Meyers ST90, just like you said a month ago in this very thread...

They are pretty popular plows. And it is even more ironic that there are a TON of them for sale for cheap around me. I think out 80 degree march and 2" of snow all winter had something to do with it???

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

Interesting idea, but wouldn't the cotter pin be in the way? I don't think you'd be able to access the inboard end of the pin without a bunch of cutting to clear some space.I was talking about drilling a hole (boring) all the way through with a couple side holes for grease to get out. That way there would be just one grease fitting on the end of the pin.

If you dont weld the back braces solid, at least drill a hole up through from the bottom, in the bottom angle, to let moisture out.

I was thinking that a drain hole would be another option... You keep reading my mind.

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

Paul, I am going to add the rear skid shoes too. Not sure if I will do the shock absorber or not. I also think I will go with a thicker plate 5/16 or 3/8 and that way I shouldn't have to reinforce it much, if any. You also have a much larger plow (and bigger HP tractor) than I do.

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

I've been mostly acquiring parts for this. After checking out the cylinders more thoroughly, I decided they weren't worth saving so I got new ones. Also got a new cutting edge and all the hardware. Picked up a heavy 3/8" SSQA plate via ebay, and some hoses/fittings and a crossover/cushion valve. That pretty much completes my buying spree, except maybe new trip springs, but those are cheap and easy to find later on.

Today I blocked out the day to pick up a sandblaster from the rental shop and go to town on it, but they discontinued carrying it. Not to be thwarted, I drove over to Northern and bought a small pressure blaster and media (Black Diamond 30-60 grit - looks like it is a locally made item that is probably similar to Black Beauty, but I'm not sure). So here's a couple pics of my setup. I used my knock down tent that I use for some wood finishing to make a barrier to contain the mess a bit. It helped but killed my back working that low. I need a better solution for that. I finished up the A frame and sector, but never got to the moldboard. That will require a day all of it's own. I had no real problems with clogging, but do wish I got the bigger model as I was refilling a lot. This is the one I got:

Allsource Abrasive Blaster with FREE U.S. Patented Deadman Handle 5-Gallons | Portable Abrasive Blasters | Northern Tool + Equipment

And here's the final result and the safety gear I used. I wore a full face with P100 filters on it, under the cheapo white hood (came with it) that I mostly used just to protect the lens of the full face mask.

Yes it is hot nasty work, but heck that's no different than what I do with the tractor on my land... The moldboard will be a PITA as the blaster is quite small - more like an airbrush than a spray gun - so it will be slow going. I may attack the big areas with a flap disk instead of blasting as it should be faster. We'll see.

The moldboard will be a PITA as the blaster is quite small - more like an airbrush than a spray gun - so it will be slow going. I may attack the big areas with a flap disk instead of blasting as it should be faster. We'll see.

Next up, I can start working on the mount, and get to blasting the moldboard when I have a good opportunity.

Today I blocked out the day to pick up a sandblaster from the rental shop and go to town on it, but they discontinued carrying it. Not to be thwarted, I drove over to Northern and bought a small pressure blaster and media (Black Diamond 30-60 grit - looks like it is a locally made item that is probably similar to Black Beauty, but I'm not sure). So here's a couple pics of my setup. I used my knock down tent that I use for some wood finishing to make a barrier to contain the mess a bit. It helped but killed my back working that low. I need a better solution for that. I finished up the A frame and sector, but never got to the moldboard. That will require a day all of it's own. I had no real problems with clogging, but do wish I got the bigger model as I was refilling a lot. This is the one I got:

Allsource Abrasive Blaster with FREE U.S. Patented Deadman Handle 5-Gallons | Portable Abrasive Blasters | Northern Tool + Equipment

And here's the final result and the safety gear I used. I wore a full face with P100 filters on it, under the cheapo white hood (came with it) that I mostly used just to protect the lens of the full face mask.

Yes it is hot nasty work, but heck that's no different than what I do with the tractor on my land...

Next up, I can start working on the mount, and get to blasting the moldboard when I have a good opportunity.

Attachments

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

This one is for LD1...or anyone else with Meyers experience.

There are a couple mods the PO made on the plow. I am curious if you have seen these before. First off, he tacked on a square pad as a turn stop (pic 1). Then he tacked on two extensions to the trip stops. You can tell the piece he added on as it looked like a rat chewed it... There was one on the other side too, but a weld was busted and it snapped off totally trying to bend it back, so I need to fix that in any case. Might as well do it right.

You ever seen these before, and should I keep them or not? In any case I need to improve the hack welding he did. Way too cold and bird poopy...

Thx

There are a couple mods the PO made on the plow. I am curious if you have seen these before. First off, he tacked on a square pad as a turn stop (pic 1). Then he tacked on two extensions to the trip stops. You can tell the piece he added on as it looked like a rat chewed it... There was one on the other side too, but a weld was busted and it snapped off totally trying to bend it back, so I need to fix that in any case. Might as well do it right.

You ever seen these before, and should I keep them or not? In any case I need to improve the hack welding he did. Way too cold and bird poopy...

Thx

Attachments

LD1

Epic Contributor

The first pic is easy. He wanted less angle. That could have been for several reasons. Maybe he had the wrong mount for the truck and it would angle till it hit the bumper?? Maybe the plow was too small to cover his wheel tracks at full angle??

There are several reasons for that.

The second two photos look interesting though. But they shouldnt be needed unless something else is tweaked or broke on the plow somewhere. I cant remember exactally what is "supposed" to stop the plow in the upright position, I'll have to look at mine this evening when I get home. But if nothing is tweaked, those shouldnt be needed.

There are several reasons for that.

The second two photos look interesting though. But they shouldnt be needed unless something else is tweaked or broke on the plow somewhere. I cant remember exactally what is "supposed" to stop the plow in the upright position, I'll have to look at mine this evening when I get home. But if nothing is tweaked, those shouldnt be needed.

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

LD1- thanks

I wondered if the pad were to reinforce the stops, but if they are just to cut the angle, I'll cut them off as that won't matter in my case.

The trip stops are another story. The angle cross piece that they are supposed to stop against is bent and even cracked, so it is on the list of things to fix. I suspect that the bend caused it to not stop reliably or get stuck so he added these longer stops. So once I fix the real issue, they should not be needed. I think I am going to replace the moldboard too. It is kinda rough, and I'd like to start fresh here rather than chase problems again down the road.

But you confirmed that these are not "normal" mods, so that tells me they need to go...

I wondered if the pad were to reinforce the stops, but if they are just to cut the angle, I'll cut them off as that won't matter in my case.

The trip stops are another story. The angle cross piece that they are supposed to stop against is bent and even cracked, so it is on the list of things to fix. I suspect that the bend caused it to not stop reliably or get stuck so he added these longer stops. So once I fix the real issue, they should not be needed. I think I am going to replace the moldboard too. It is kinda rough, and I'd like to start fresh here rather than chase problems again down the road.

But you confirmed that these are not "normal" mods, so that tells me they need to go...

LD1

Epic Contributor

LD1- thanks

I wondered if the pad were to reinforce the stops, but if they are just to cut the angle, I'll cut them off as that won't matter in my case.

The trip stops are another story. The angle cross piece that they are supposed to stop against is bent and even cracked, so it is on the list of things to fix. I suspect that the bend caused it to not stop reliably or get stuck so he added these longer stops. So once I fix the real issue, they should not be needed. I think I am going to replace the moldboard too. It is kinda rough, and I'd like to start fresh here rather than chase problems again down the road.

But you confirmed that these are not "normal" mods, so that tells me they need to go...

Yea, the bent trip stop isnt a normal mod. That is someone trying a band-aid instead of fixing the real problem.

The tabs on the stops, that is more common to limit the amound of angle. Various reasons why that could have been done, but those pads dont look like it is robbing you of that much angle. And they are almost not noticable, I dont think I would take the time to mess with them. But thats just me.

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

It appears this is pretty much becoming my snow plow build thread....

I took the moldboard off the frame today. That was fun:confused2: I picked up an oxy/propane torch Fri as I knew I couldn't do this with cutoff wheels, and I have been planning to get a torch for some time. I didn't want to deal with yet another cylinder, and propane is easy and a bit safer than acetylene, so that is why I went that way. I could only fit a 125 cf O2 cyl in my available space, so I got that even though I knew it was on the small side. They will give me full credit on the lease when I have room to upgrade to the 282 cf tank.

I always struggled with torch cutting when I was taking my welding class at the CC, and I sure haven't gotten any better since. I ended up having to peel out sections of the modlboard as I couldn't hit the welds only to release it (like I said, I stink at torch cutting...). In the end I completely drained the O2 tank doing this, which didn't totally surprise me as I had read you use a ton of O2 on oxy/propane. But I got it done. Rusty, but still seems structurally solid enough.

I ended up having to peel out sections of the modlboard as I couldn't hit the welds only to release it (like I said, I stink at torch cutting...). In the end I completely drained the O2 tank doing this, which didn't totally surprise me as I had read you use a ton of O2 on oxy/propane. But I got it done. Rusty, but still seems structurally solid enough.

Now need to clean up with grinder and then sandblast it, plus put in a new cross member where the old one was mangled and broken. Then I will bring it to a shop to get a moldboard rolled and start the reassembly/welding.

A couple pics of today... (couldn't have picked a hotter, nastier day to do this too...)

I took the moldboard off the frame today. That was fun:confused2: I picked up an oxy/propane torch Fri as I knew I couldn't do this with cutoff wheels, and I have been planning to get a torch for some time. I didn't want to deal with yet another cylinder, and propane is easy and a bit safer than acetylene, so that is why I went that way. I could only fit a 125 cf O2 cyl in my available space, so I got that even though I knew it was on the small side. They will give me full credit on the lease when I have room to upgrade to the 282 cf tank.

I always struggled with torch cutting when I was taking my welding class at the CC, and I sure haven't gotten any better since.

Now need to clean up with grinder and then sandblast it, plus put in a new cross member where the old one was mangled and broken. Then I will bring it to a shop to get a moldboard rolled and start the reassembly/welding.

A couple pics of today... (couldn't have picked a hotter, nastier day to do this too...)