I wasn't going to update this thread again until the processor was done, the video was made and I could show all the updates I'm working on. Well, the wood processor gods don't seem to want this project to ever finish and I'm now under doctor orders not to work on it for one to two weeks (more on that in a minute), so I might as well give a quick update.

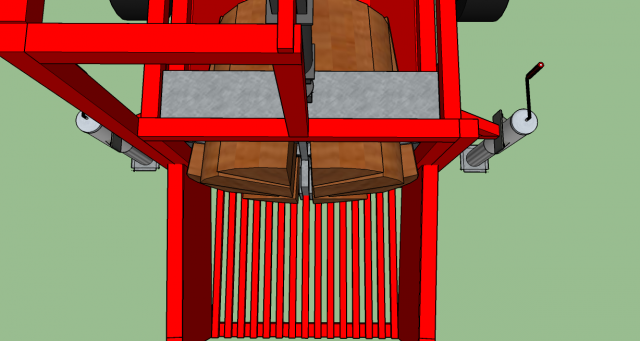

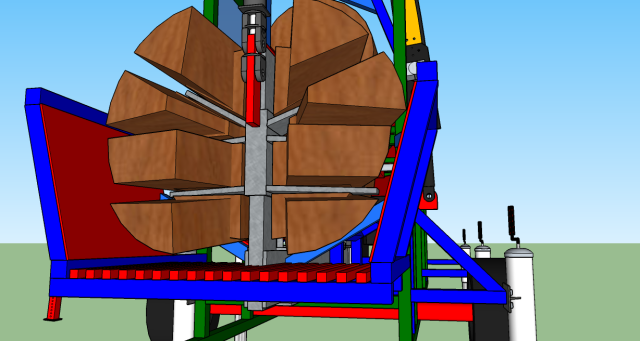

I started working on it again on Monday. I first figured out how to attach the conveyor to the processor. This is what I came up with.

Then I mocked it up.

That's were I stopped taking pictures, but I managed to paint the frame that holds the new tank, I drained the old tank and hooked up the new tank. I even added 5 gallons of fluid that came out of the old tank, and there are no leaks with it just sitting there. On the conveyor, I mounted the electric motor from my cement mixer with a bracket on the side. I finished welding the conveyor and painted it. I was just about to take the flap disc to clean up the tensioning system to allow it to move smoothly then install the springs when I had a little accident and the reason I'm not supposed to work on it for a little while.

Last night at 11, I was going to use the grinder as I said above. My extension cord was plugged into a drill that was 6-8 feet away and that was wrapped around the base of a ladder. The plug end was on my side of the ladder, so being lazy, I just pulled gently on the extension cord to pull the drill free instead of walking the whole 8 feet and having to reach down to unplug it by hand. It didn't come loose, so I gave it a quick yank. The end of the cord flew straight up and hit me squarely in the eye. It doesn't sound like that would be a big deal, but I've never been hit so hard or been in so much pain. I knew I messed up my eye but I couldn't see, so I went in the house, woke up my wife and we inspected the damage. It scared me enough to instantly agree to go the the hospital, and I won't go to the hospital for anything. We had to wake the 3 kids up and drive the 40 minutes to the General hospital because that's where the eye institute is. I was seen right away, told there was internal bleeding and swelling and that I needed to come back the next morning for another follow up. I was back again today and they confirmed the bleeding was stopped but it was still an issue and there's still lots of swelling. I was told I can't lift anything heavy because straining can cause the bleeding to start again.

It was both the most painful injury I can remember and the scariest since I felt like I was in a deep fog, which was apparently blood behind the eye and has thankfully cleared now. Even so, I still have my fighter pilot 20-15 vision in that eye, not bad for an old fart!

I only need 5 or 6 hours to finish it. See you in a few weeks...

Are your connections done, so you could do a test run before going any further into your build?

Are your connections done, so you could do a test run before going any further into your build?

![IMG_20150617_225913[1].jpg IMG_20150617_225913[1].jpg](https://www.tractorbynet.com/forums/data/attachments/385/385771-0574661a02f467f7591aa62f712a0e2a.jpg)