Snobdds

Super Member

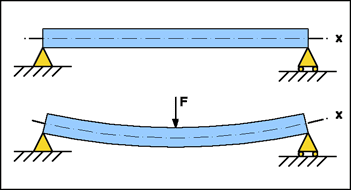

Besides, I don't like that anatomy figure. They act like a gluelam has seperate areas of function. It's one big beam that is all glued under pressure. It acts like one piece of wood. There are no slipper plates to divide the beam into different areas of forces.

I get over-simplication for comprehension, but that is bad.

I get over-simplication for comprehension, but that is bad.