Gapping and beveling are very important for full penetration welds. Less than 1/16" gap is not necessary. Over that the gap needs to be the width that the rod/wire is in diameter. Over 3/16" beveling needs to start. The land at the bottom again as wide as the rod diameter. Poor fit up gap (like manual flame cutting) at the widest opening. 4.5" grinder is your tool of choice for creating the land and bevel. With SMAW root pass needs to be done with a penetrating fast freeze rod like 6010/6011. MIG I am not an expert.

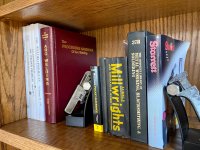

If you are serious about quality arc welding of all methods SMAW, MIG, TIG and their variations invest in Lincoln's "Procedure Handbook of arc Welding". It is the Industry Bible and used at most welding schools as there textbook of choice. Well worth the $60 on Amazon. If you can afford a decent welding machine you can afford the manual. There are a myriad of other help books there also. The small hand books are great for, in the shop/pocket" ready reference.

Ron