You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hydrostatic ATV

- Thread starter kdlklm

- Start date

- Views: 74900

More options

Who Replied?

/ Hydrostatic ATV

#81

kubotakid USA

Silver Member

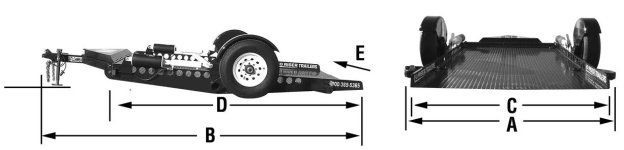

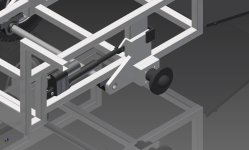

What about similar to this Lo Riser trailer design.

Again I like the orignal design, First post last pic, shows the kneeling action, I would build it very simular, with the exception, that I would set the cylinder back, using a longer rod, Simular to the kneeling trailer pic, Ive had the ride factor pluged in from the start, and Iam leaning towards an independant supension, meaning not tying each axle together, with a cross tube, and using air cylinders, instead of hydraulic for the kneeling action, and ultimatly then I can use them for an AIR RIDE, Suspension, :thumbsup: simple to do, and very nice ride, you not only have air ride, but independant suspension, ta boot,:thumbsup: And my front axle would pivot at the articulating point, with shocks. Should result in a pretty nice ride. The false floor has many flaws and offers little. Eric

aczlan

Good Morning

- Joined

- Mar 7, 2008

- Messages

- 17,540

- Tractor

- Kubota L3830GST, B7500HST, BX2660. Formerly: Case 480F LL, David Brown 880UE

Again I like the orignal design, First post last pic, shows the kneeling action, I would build it very simular, with the exception, that I would set the cylinder back, using a longer rod, Simular to the kneeling trailer pic, Ive had the ride factor pluged in from the start, and Iam leaning towards an independant supension, meaning not tying each axle together, with a cross tube, and using air cylinders, instead of hydraulic for the kneeling action, and ultimatly then I can use them for an AIR RIDE, Suspension, :thumbsup: simple to do, and very nice ride, you not only have air ride, but independant suspension, ta boot,:thumbsup: And my front axle would pivot at the articulating point, with shocks. Should result in a pretty nice ride. The false floor has many flaws and offers little. Eric

What if you used a short axle (such as for a jet ski trailer) as your pivot points (mount the swingarms where the wheels would go), used hydraulics for the lifting the axle and put a pair of accumulators (with solenoids to allow them to be shut off) on the lifting line of the cylinder?

That should allow you to lift the swing-arms and (if you also installed a pair of pressure gauges) you could set your ride height/firmness based on pressure.

Aaron Z

kubotakid USA

Silver Member

What if you used a short axle (such as for a jet ski trailer) as your pivot points (mount the swingarms where the wheels would go), used hydraulics for the lifting the axle and put a pair of accumulators (with solenoids to allow them to be shut off) on the lifting line of the cylinder?

That should allow you to lift the swing-arms and (if you also installed a pair of pressure gauges) you could set your ride height/firmness based on pressure.

Aaron Z

Air ride is much more sensitive, I thought about hydraulic accumulators, but buy the time you buy the accumulators, (2), and electric silinoids, and add the control valve, your spending sum real C@SH, and dont have the nice ride,air gives you, The 12 volt air compressor is going to run around 100-125 for good quality, and air valves,switches,fittings,gages, etc are CHEAP, and much eaiser to dial in the ride, Eric

Iplayfarmer

Super Member

where would you suggest putting in the hydraulic Rams to lift it, on this particular design.

The drawing was incomplete. I was picturing a system where the middle part had rails, etc. build up off of it. The rams could connect from a point on the upper rails to the swing arm.

mjncad

Super Member

I just came across this cool thread.

KDLKLM, are you using Inventor or Solidworks for your CAD program?

If you go with the false/hinged floor, how about DPOCV (Double Pilot Operated Check Valves) to keep hydraulic cylinder leak down and drift in check?

How about 12VDC linear actuators for the false/hinged floor? I've seen some at Surplus Center rated to 1,000 pounds. Using these for secondary systems such as the floor would be simpler and cheaper than hydraulics.

As KennyD is fond of saying, "The only thing cheap about hydraulics is O-rings and advice."

It sounds like the OP has highly limited mobility and will require as much electro/hydro/mechanical help as possible. Solenoids could be useful for lashing down his chair, etc.

My concern with the false/hinged floor is from the top the main frame looks like a large "C" and needs something at the front to latch securely to minimize racking laterally. How about an "R" (closest letter I could find) frame where the floor pivot is in the middle? This would give you two solid crossmenber points instead of one with the "C" configuration. Granted the slope for your chair will be steeper; but the fold up ramp could be designed with an angle to act as a transition from the chair deck to the ground.

Tracks may be cool; but I think they'll give you more grief getting them to function properly.

KDLKLM, are you using Inventor or Solidworks for your CAD program?

If you go with the false/hinged floor, how about DPOCV (Double Pilot Operated Check Valves) to keep hydraulic cylinder leak down and drift in check?

How about 12VDC linear actuators for the false/hinged floor? I've seen some at Surplus Center rated to 1,000 pounds. Using these for secondary systems such as the floor would be simpler and cheaper than hydraulics.

As KennyD is fond of saying, "The only thing cheap about hydraulics is O-rings and advice."

It sounds like the OP has highly limited mobility and will require as much electro/hydro/mechanical help as possible. Solenoids could be useful for lashing down his chair, etc.

My concern with the false/hinged floor is from the top the main frame looks like a large "C" and needs something at the front to latch securely to minimize racking laterally. How about an "R" (closest letter I could find) frame where the floor pivot is in the middle? This would give you two solid crossmenber points instead of one with the "C" configuration. Granted the slope for your chair will be steeper; but the fold up ramp could be designed with an angle to act as a transition from the chair deck to the ground.

Tracks may be cool; but I think they'll give you more grief getting them to function properly.

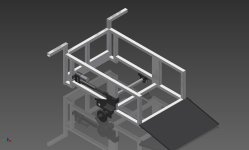

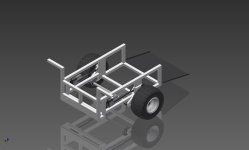

I think I've got something here, that I'm very happy with. I've taken bits and pieces of excellent advice from many different people. The linear actuator was something I've been thinking about for some time. I've got ones that I use several times a day, that I've had for 20 years and they still work as good as the day I got them. So I think they're a good option. The ones I put on here have a lifting capacity of 750 pounds. Which is more than enough. They would be so much simpler to install, not needing hoses, pumps and etc.

I haven't incorporated the ramp yet. I put a shaft going right through the floor which should give it a great deal of strength. But I'm just waiting to get some input on my progress so far. Let me know what you think.

Keith

I haven't incorporated the ramp yet. I put a shaft going right through the floor which should give it a great deal of strength. But I'm just waiting to get some input on my progress so far. Let me know what you think.

Keith

Attachments

aczlan

Good Morning

- Joined

- Mar 7, 2008

- Messages

- 17,540

- Tractor

- Kubota L3830GST, B7500HST, BX2660. Formerly: Case 480F LL, David Brown 880UE

Are they waterproof? One advantage to hydraulics or air is that they dont mind getting wet.The linear actuator was something I've been thinking about for some time. I've got ones that I use several times a day, that I've had for 20 years and they still work as good as the day I got them. So I think they're a good option. The ones I put on here have a lifting capacity of 750 pounds. Which is more than enough. They would be so much simpler to install, not needing hoses, pumps and etc.

Aaron Z

Are they waterproof? One advantage to hydraulics or air is that they dont mind getting wet.

Aaron Z

I will definitely have to find ones that are going to be waterproof, and can withstand pressure washing. And if they don't exist, I will just go the hydraulic route. The hydraulic company doing the specs and prices has already incorporated that in.

Iplayfarmer

Super Member

...I'm just waiting to get some input on my progress so far. Let me know what you think...

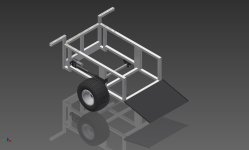

Brilliant! Retractable wheels.

mjncad

Super Member

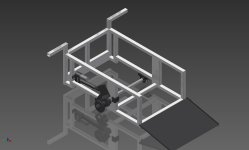

The frame looks better with the extra cross-members. This is a better design whether you use hydraulics, pneumatics, or linear actuators.

What about linear actuators used for wheelchair lifts on vans that don't have air brakes? I suspect those things see quite a bit of muck.

What about linear actuators used for wheelchair lifts on vans that don't have air brakes? I suspect those things see quite a bit of muck.

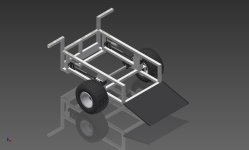

the latest photos, I'm feeling really good about this design now. Does anybody see anything that you don't like about it. The feedback is been invaluable. It's very much appreciated. Especially the ones that took all the time to do the sketches. Let me know what you think.

Attachments

mjncad

Super Member

Thinking about this more I'm wondering if you're going to put some sort of counterweight on the engine side of the vehicle. Since the wheelchair compartment side will weigh in around 600-pounds as I recall, and that Subaru or similar engine isn't going to weigh nearly that much. Even if you had a hydraulic reservoir as large as 20-gallons, you're still only looking at about 120 - 130 pounds in hydraulic fluid weight.

Also since this is an ATV, I'm wondering about suspension for the wheels, or are you relying on low pressure in the tires for soaking up the bumps? I'm thinking you could be in for a bone rattling ride even at low speeds.

I'm also starting to wonder if an articulated vehicle is the best choice. Obviously you can't straddle an engine being in a wheelchair; but I'm wondering if some sort of arrangement could be designed where you're sitting more or less between the axles instead of over one of them would make for a better ride and stability, and the maybe less complexity.

In any case, this is a fun thread due to the design challenges.

Also since this is an ATV, I'm wondering about suspension for the wheels, or are you relying on low pressure in the tires for soaking up the bumps? I'm thinking you could be in for a bone rattling ride even at low speeds.

I'm also starting to wonder if an articulated vehicle is the best choice. Obviously you can't straddle an engine being in a wheelchair; but I'm wondering if some sort of arrangement could be designed where you're sitting more or less between the axles instead of over one of them would make for a better ride and stability, and the maybe less complexity.

In any case, this is a fun thread due to the design challenges.

Thinking about this more I'm wondering if you're going to put some sort of counterweight on the engine side of the vehicle. Since the wheelchair compartment side will weigh in around 600-pounds as I recall, and that Subaru or similar engine isn't going to weigh nearly that much. Even if you had a hydraulic reservoir as large as 20-gallons, you're still only looking at about 120 - 130 pounds in hydraulic fluid weight.

Also since this is an ATV, I'm wondering about suspension for the wheels, or are you relying on low pressure in the tires for soaking up the bumps? I'm thinking you could be in for a bone rattling ride even at low speeds.

I'm also starting to wonder if an articulated vehicle is the best choice. Obviously you can't straddle an engine being in a wheelchair; but I'm wondering if some sort of arrangement could be designed where you're sitting more or less between the axles instead of over one of them would make for a better ride and stability, and the maybe less complexity.

In any case, this is a fun thread due to the design challenges.

I did strategically place the front wheels for the weight transfer balance. The weight on the front wheels should be almost exactly the same as the weight on the back wheels. And when I drive off the rear weight should be adequate.

A suspension system has been tossed around for a little while, and I think it's something I really want to do. Air ride was one of the suggestions, but I'm open to anything at this point. I'm hoping to start building in a couple weeks so I really need to come up with something quick.

The articulating design, is probably one the simplest designs, especially when it comes to steering. The hydraulics and electronics are very simple to.

Thanks for your input, I highly encourage any opinions or suggestions.

aczlan

Good Morning

- Joined

- Mar 7, 2008

- Messages

- 17,540

- Tractor

- Kubota L3830GST, B7500HST, BX2660. Formerly: Case 480F LL, David Brown 880UE

A suspension system has been tossed around for a little while, and I think it's something I really want to do. Air ride was one of the suggestions, but I'm open to anything at this point. I'm hoping to start building in a couple weeks so I really need to come up with something quick.

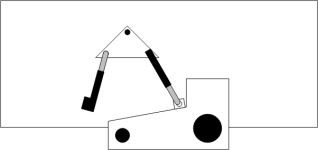

How about something like this:

With a motorcycle spring/shock on the load side and a actuator/ram on the other?

Aaron Z

(This post contains attachment # 210,000...)

How about something like this:

View attachment 210000

With a motorcycle spring/shock on the load side and a actuator/ram on the other?

Aaron Z

(This post contains attachment # 210,000...)

I got thinking about how the suspension will react when I'm driving my chair off the ramp. When I drive my front wheels off, half the weight of my chair is off the machine which will make the suspension spring up and make my chair wanna flip forward. The same thing happens with my wheelchair lift on my van, if it's not flat on the ground. I will have to come up with a workaround for that.

aczlan

Good Morning

- Joined

- Mar 7, 2008

- Messages

- 17,540

- Tractor

- Kubota L3830GST, B7500HST, BX2660. Formerly: Case 480F LL, David Brown 880UE

I got thinking about how the suspension will react when I'm driving my chair off the ramp. When I drive my front wheels off, half the weight of my chair is off the machine which will make the suspension spring up and make my chair wanna flip forward. The same thing happens with my wheelchair lift on my van, if it's not flat on the ground. I will have to come up with a workaround for that.

I would have a stop where you lower it, then when you drop it all of the way down, it is resting on the stop instead of the shock/spring.

Aaron Z

I would have a stop where you lower it, then when you drop it all of the way down, it is resting on the stop instead of the shock/spring.

Aaron Z

I would have to come up with a way to put it into the lowering system. Because if I put it underneath it will reduce my ground clearance. And I don't want do that. Do you have any suggestions.

aczlan

Good Morning

- Joined

- Mar 7, 2008

- Messages

- 17,540

- Tractor

- Kubota L3830GST, B7500HST, BX2660. Formerly: Case 480F LL, David Brown 880UE

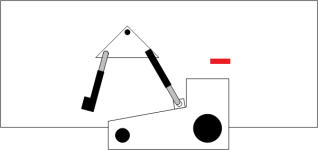

Make the actuator/ram longer than the shock and put in a stop with a rubber "bumper" (shown in red below) to end travel for the swing armI would have to come up with a way to put it into the lowering system. Because if I put it underneath it will reduce my ground clearance. And I don't want do that. Do you have any suggestions.

Then to put it into "kneeling" position you retract the actuator/ram until the spring is unloaded and the arm is resting on the bump stop (perhaps even put in a sensor to turn on a light when that happens)

Aaron Z

Make the actuator/ram longer than the shock and put in a stop with a rubber "bumper" (shown in red below) to end travel for the swing arm

View attachment 210331

Then to put it into "kneeling" position you retract the actuator/ram until the spring is unloaded and the arm is resting on the bump stop (perhaps even put in a sensor to turn on a light when that happens)

Aaron Z

that's a good idea, I wonder if there is a shock absorber that would attach directly to the end of the actuator. Have one that screws on to the end. Because if I had just a few inches of travel, that would probably be more than adequate. I have seen shock absorbers that are that small.

But that would probably bring me back to my original problem of having the front-end spring up, when driving off the machine.

Here are some similar links:

- Replies

- 0

- Views

- 941

- Replies

- 2

- Views

- 2K